Automotive Safety System Production Line Launch

Verification & Validation

1. Project Overview

Problem statement

Verification and validation of new processes and equipment to ensure new products can be built at high capacity with accurate and repeatable quality.

Key Tasks

- Verification & Validation

- Statistical Process Control (SPC)

- Process Engineering

- Continuous Improvement

- New Product & Process Introduction

- PLC

Team

Project Lead Engineer, Jason

Product Lead Engineer, Edbert

Mechanical Engineer, Archi

Intern Mechanical Engineer, James

Controls Engineer, Hervin

Test Engineer, Kuru

2. Process and Work

The project can be broken down into these steps:

- Initial start-up.

- Optimize each equipment and process to meet target cycle time.

- Validate a sample of manufactured products using SPC and inspections.

- Perform a full-speed trial (PV) build and validate finished goods, documenting any downtime or stoppages.

- Troubleshoot at all stages, as needed.

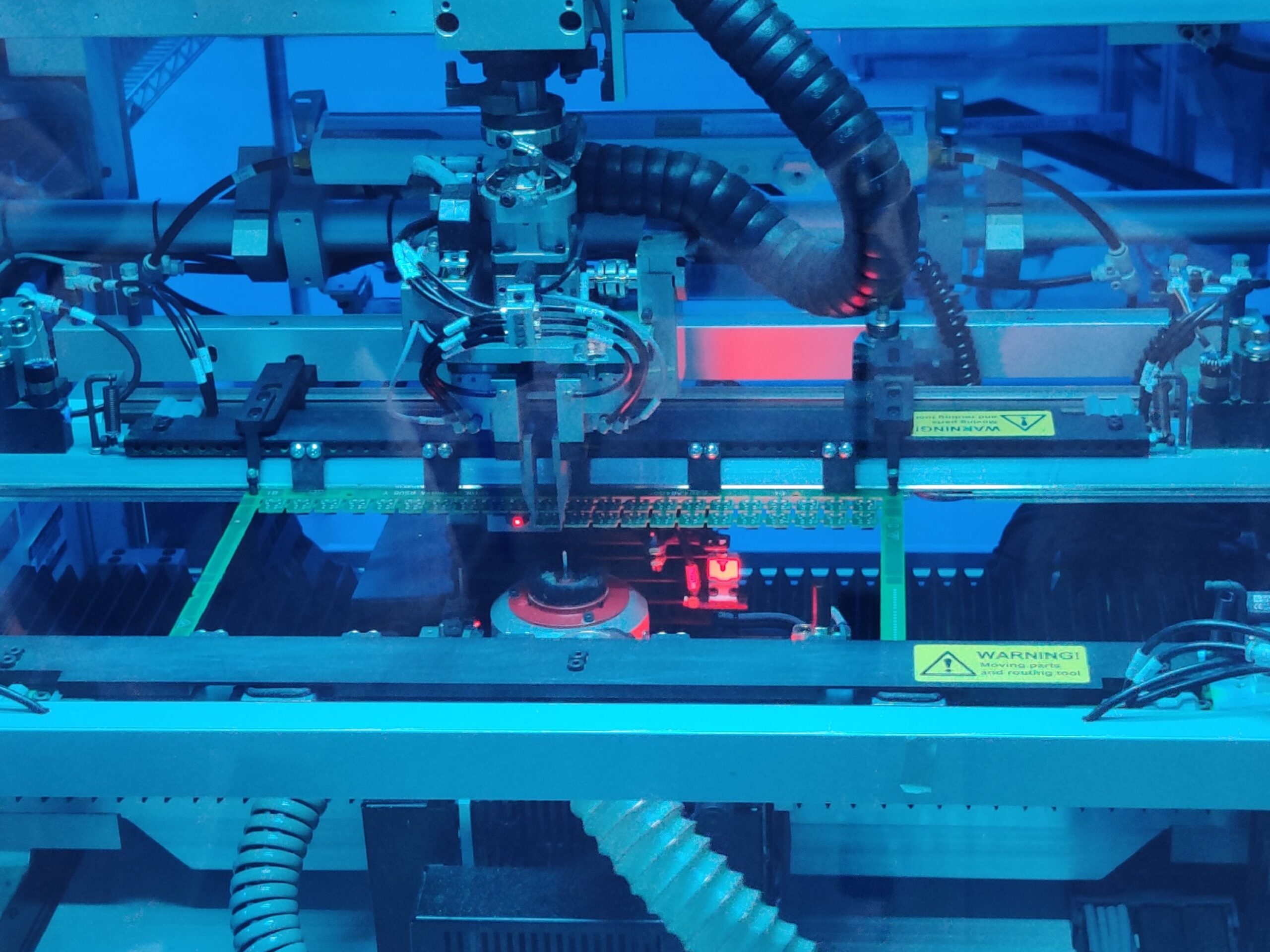

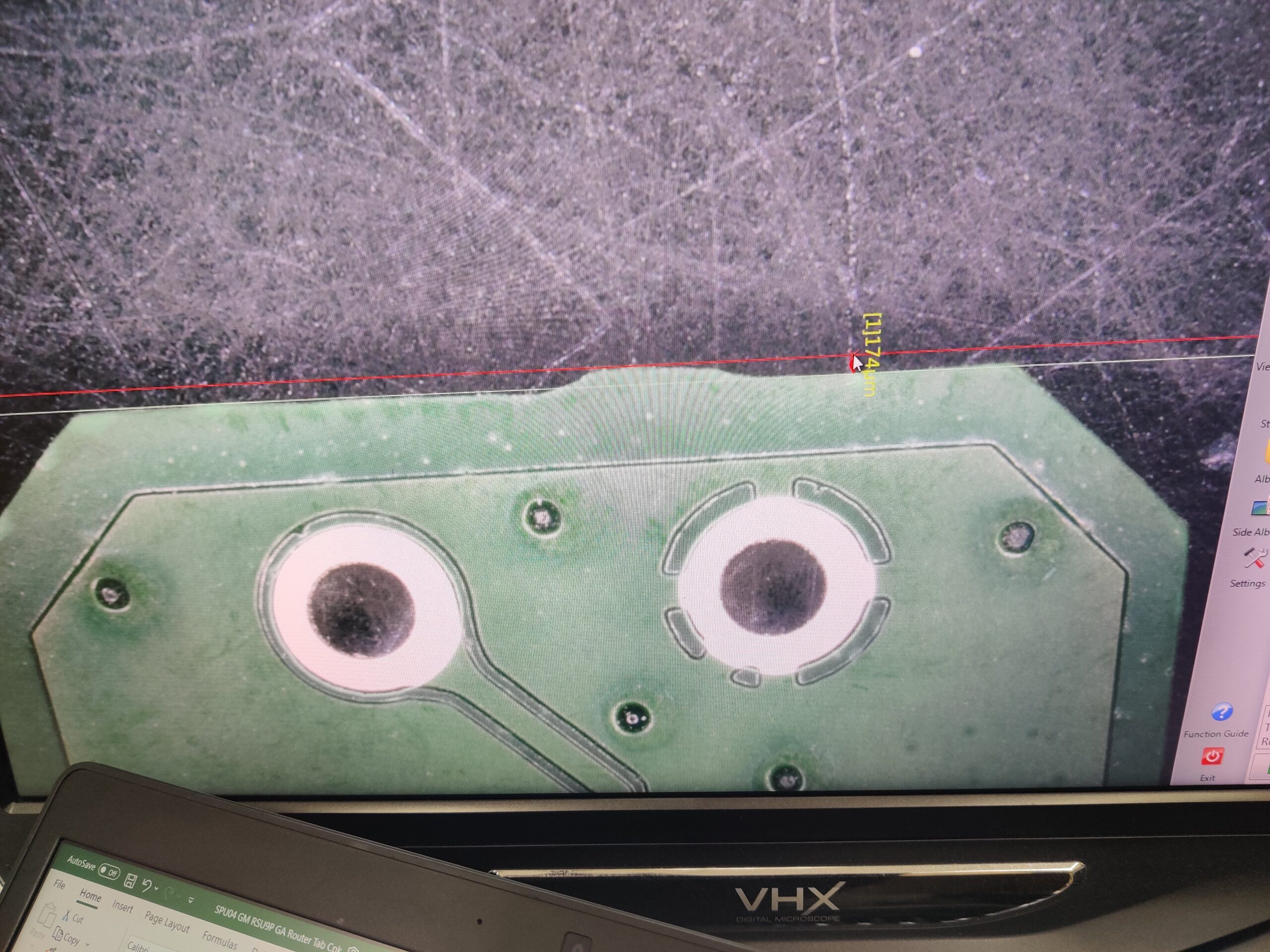

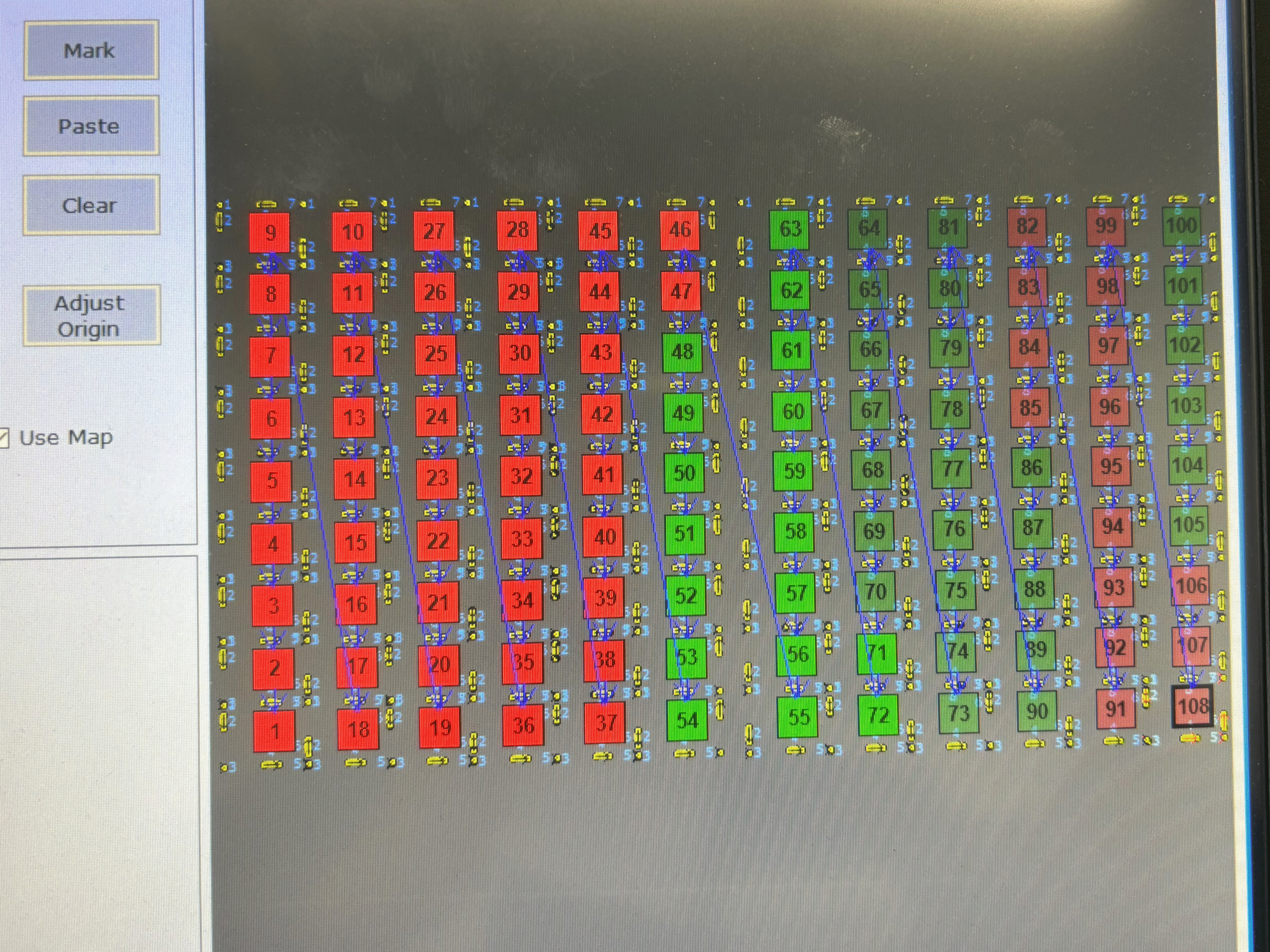

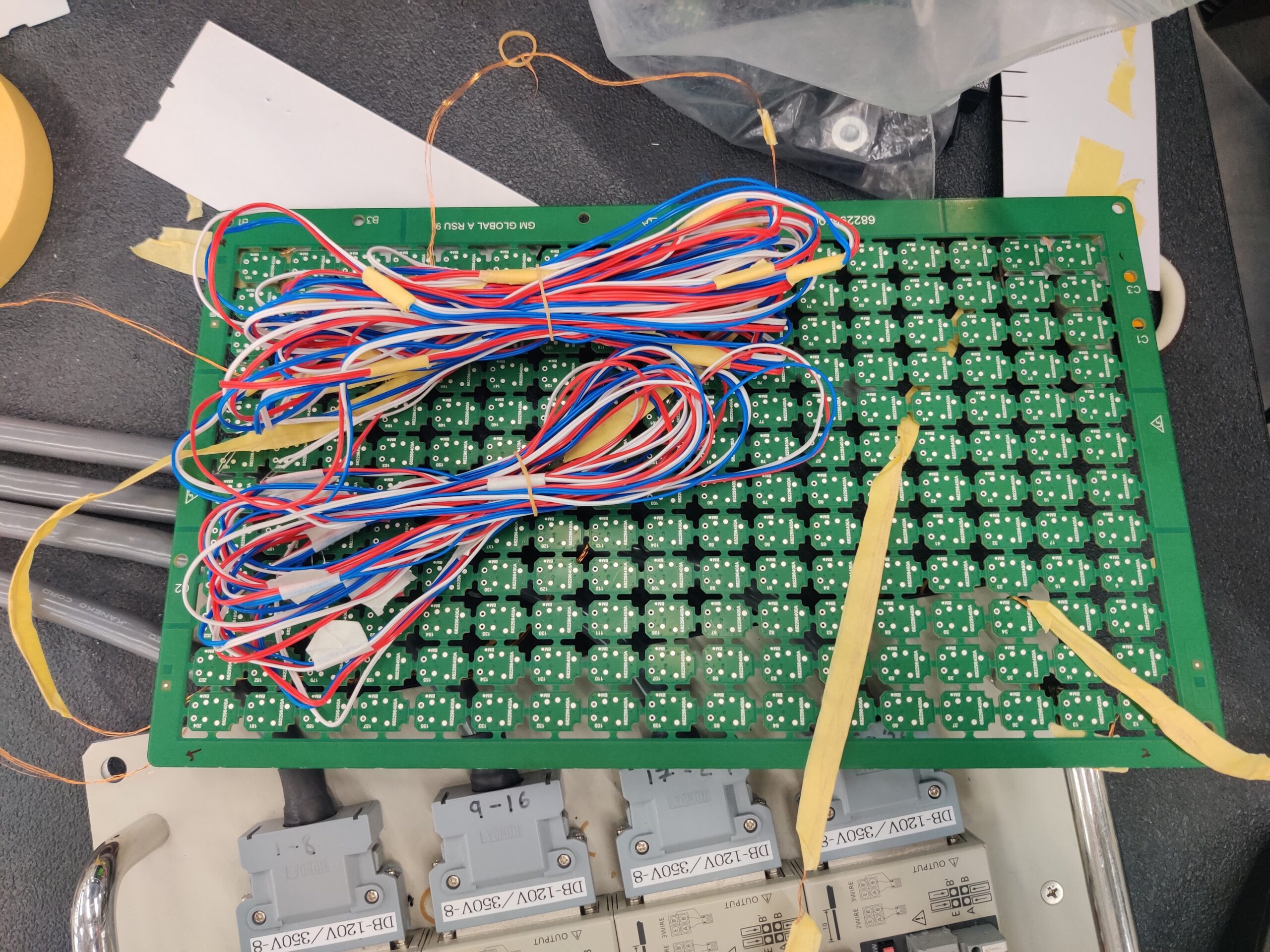

Depaneling/PCB Cutting

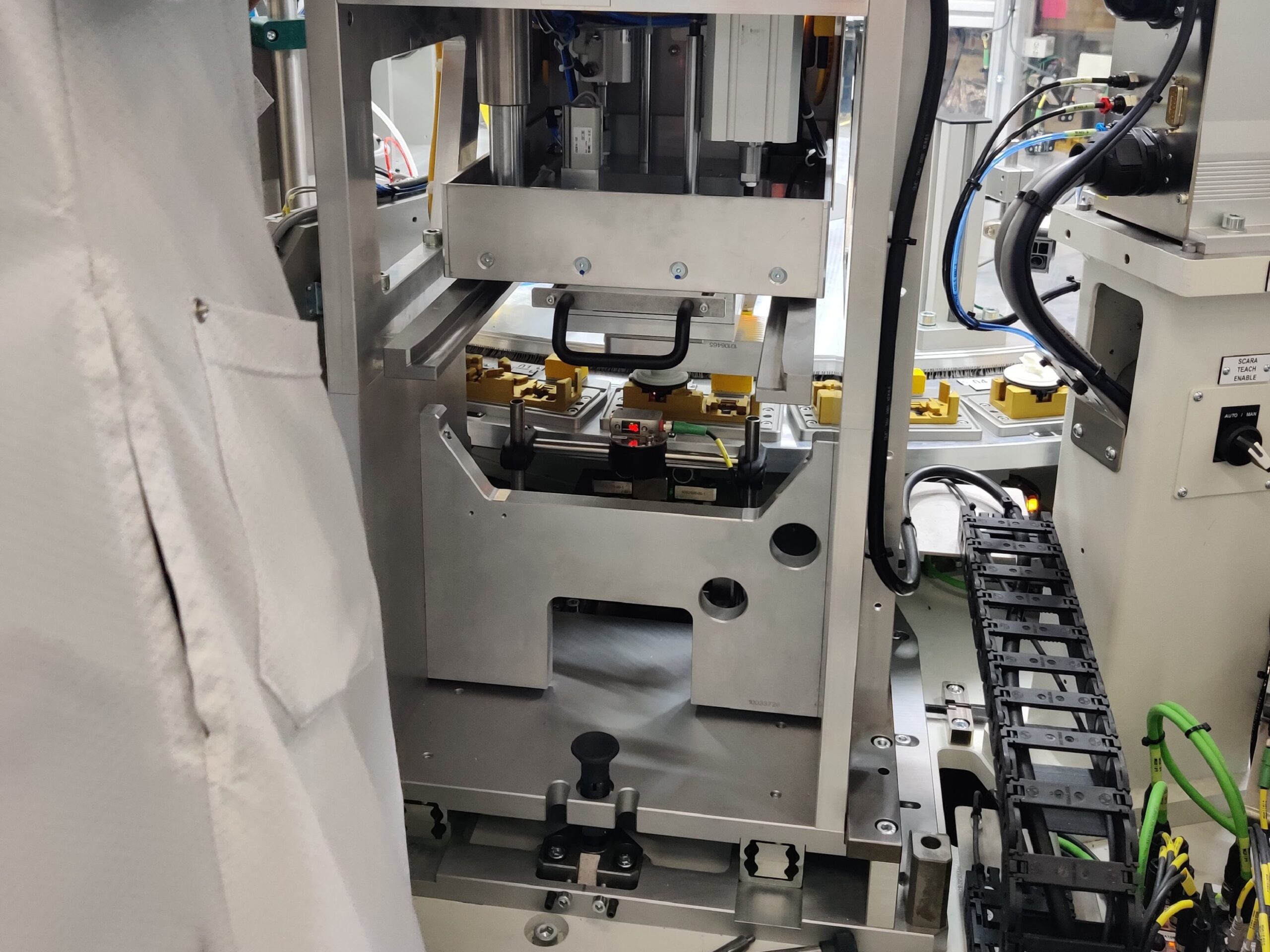

Performed validation on new product processes and new Cencorp BR 1000 equipment. I interfaced with the HMI to create new programs using close-up cameras to set parameters like the cutting path, sequence, and exceptions. I ran tests with bare PCB motherboards boards to ensure every daughterboard was cut in accordance to the design specifications. I conducted Cpk studies using a minimum sample size of 30 cut-PCBAs and measuring the tabs on each side of the board using a microscope, using Minitab to process the data. I validated 5 product families, making any necessary machine modifications and troubleshooting to achieve minimum 1.62 Cpk values.

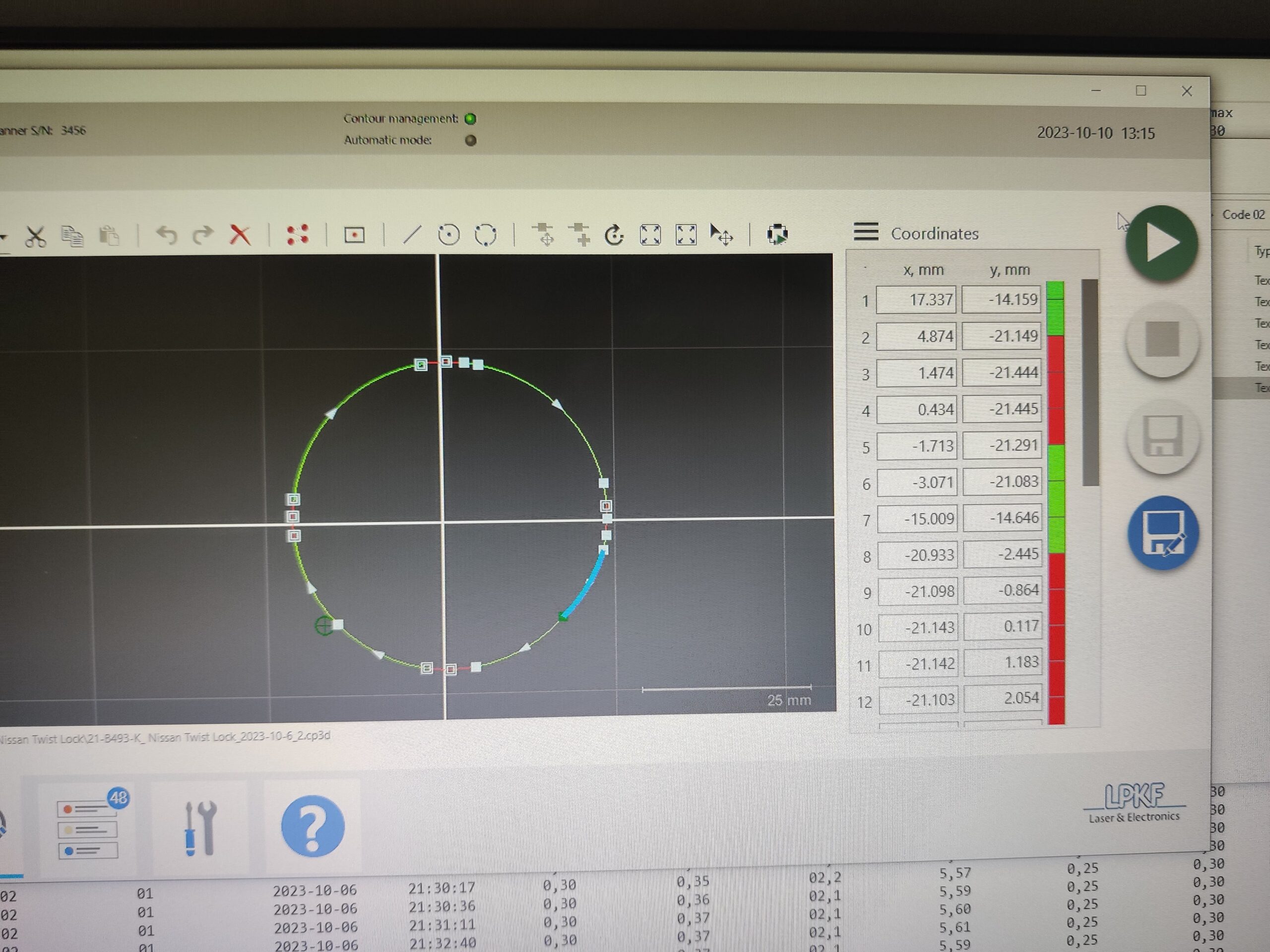

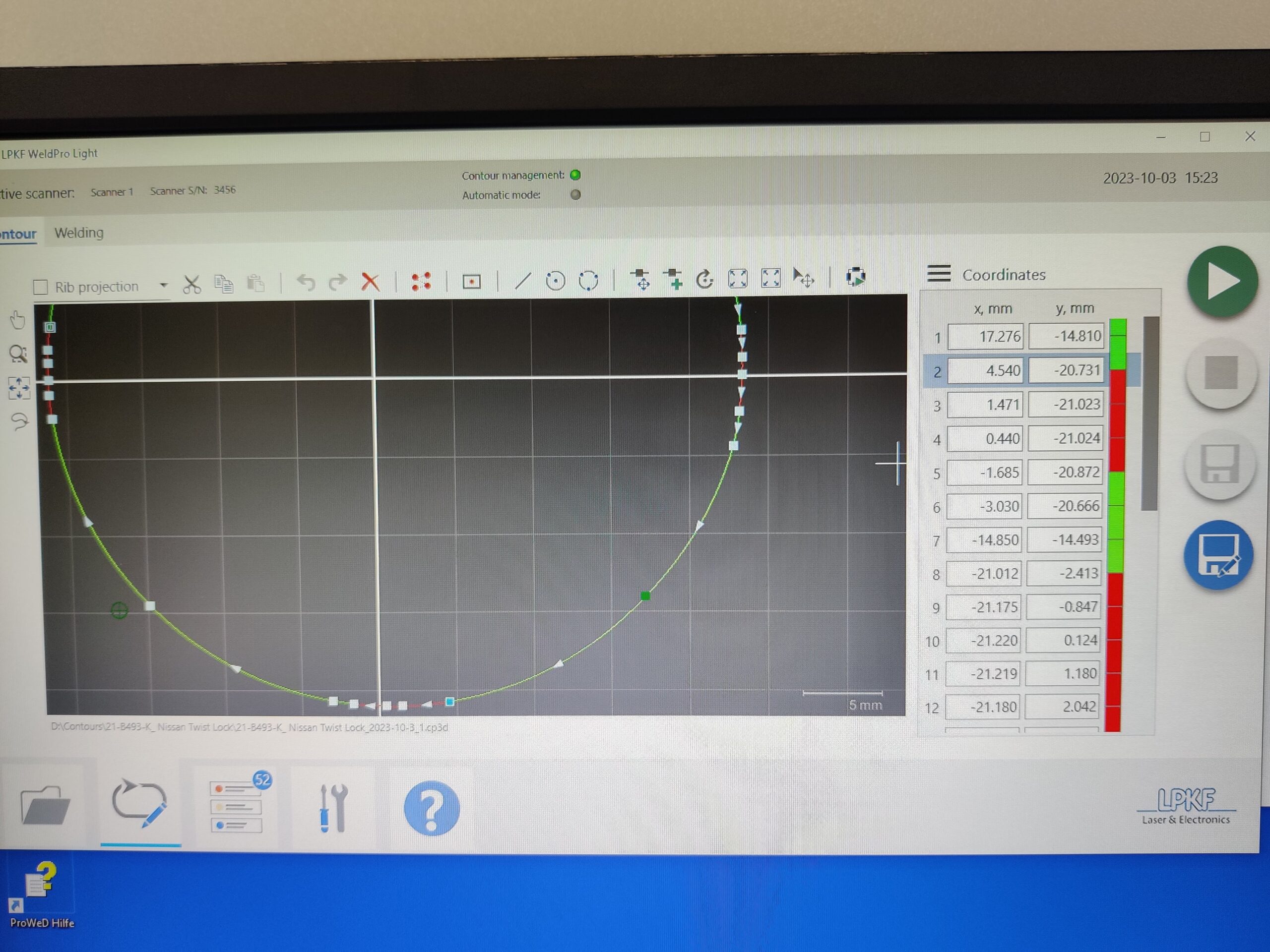

Laser Weld

Optimized LPKF laser weld process to reduce bottle-neck cycle time from 6.7 secs to 5.5 secs. Conducted sensitivity analyses to determine relationship between adjusting a process parameter and its effect on the overall cycle time. I interfaced with a Siemens HMI to configure power, clamping force, laser path, and laser speed. I conducted multiple photo burn paper tests to examine weld quality after making parameter changes to determine areas of improvement.

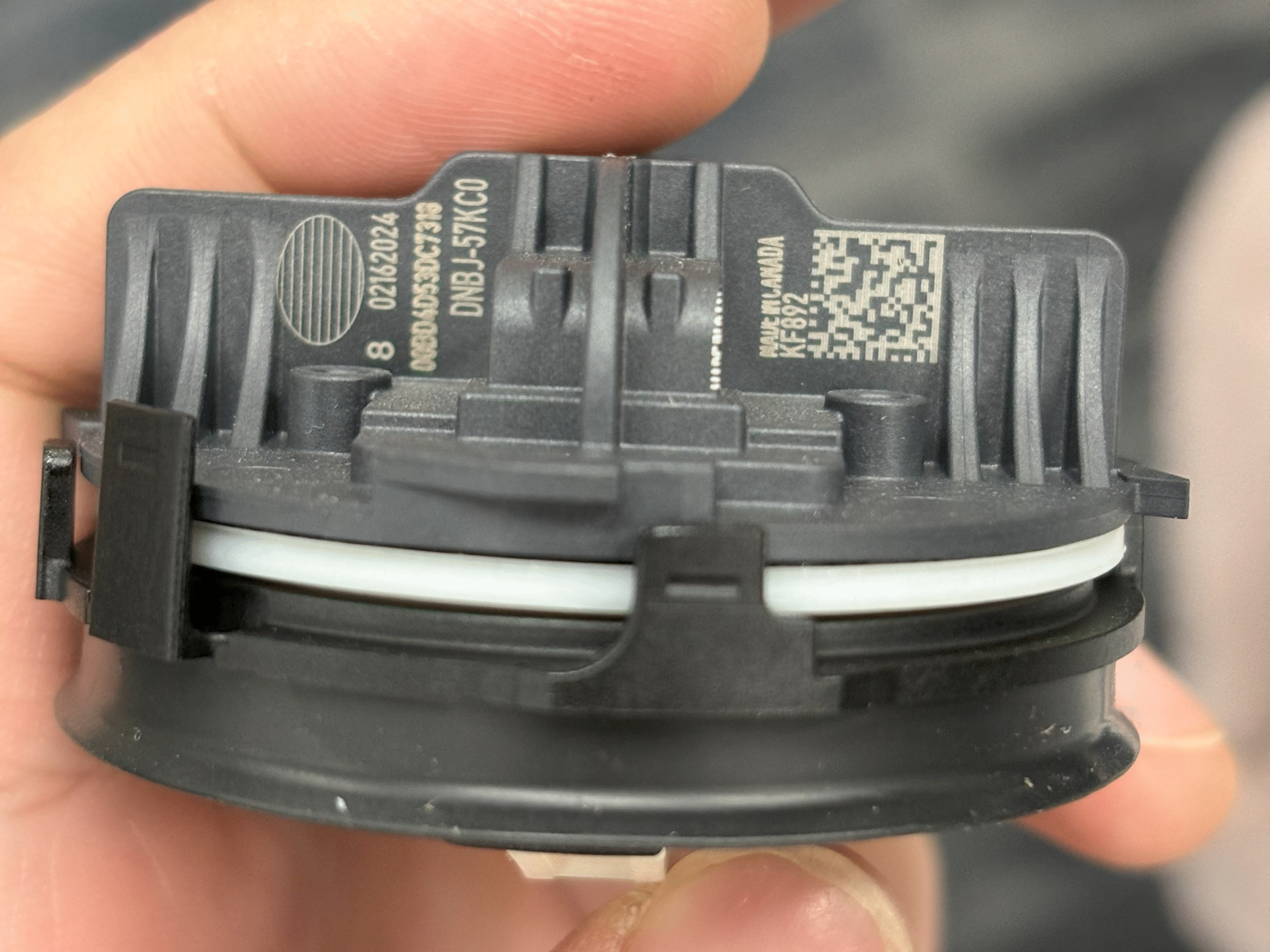

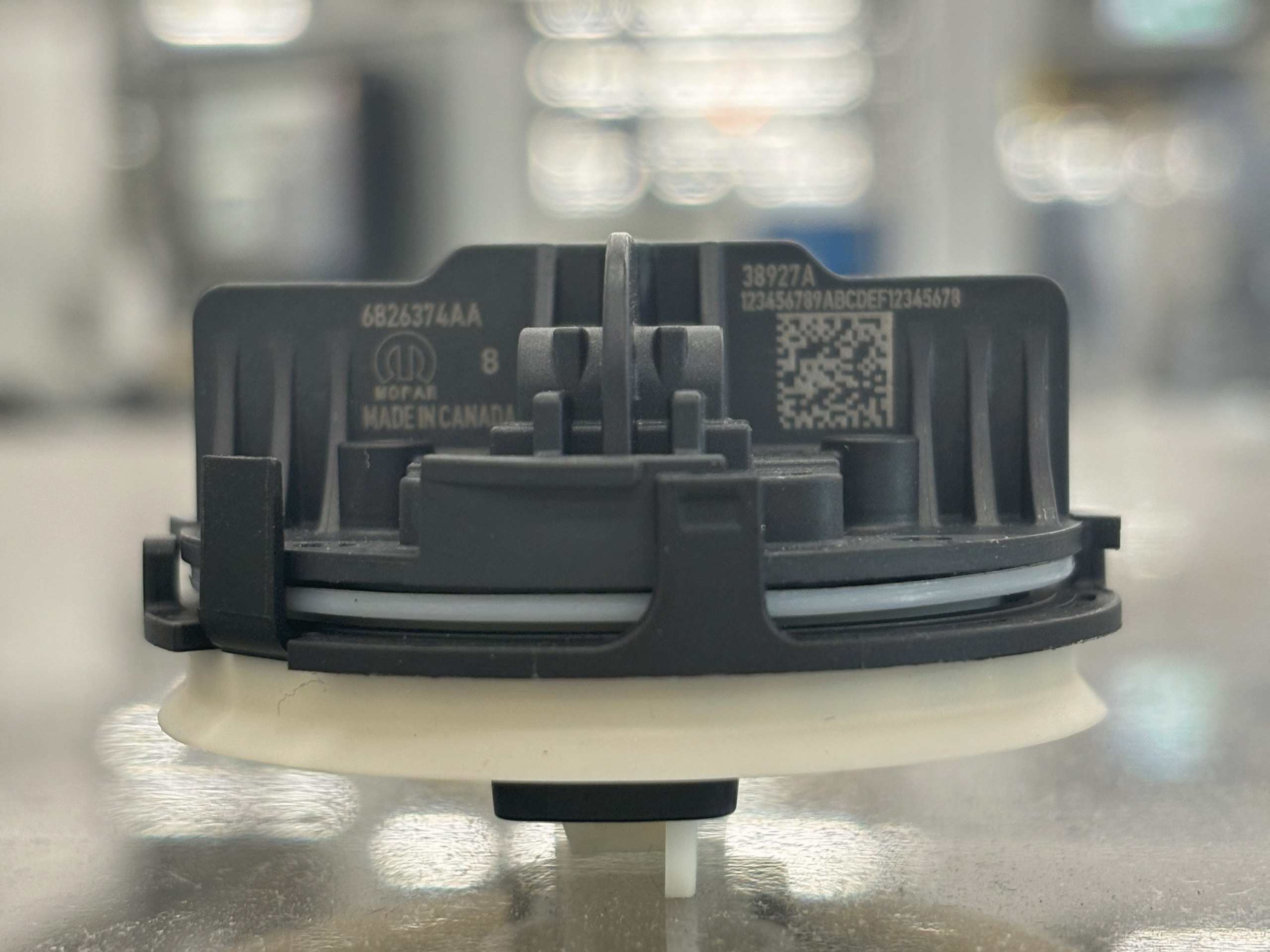

Laser etch

Validated precision and accuracy of TRUMPF laser etch for marking important customer product information onto finished products, such as serial numbers, manufacturing date, location, etc. I conducted Cpk tests using a minimum sample size of 30 finished goods, comparing measured positions of each etching against the values indicated on technical drawings using microscopes and hand calipers. Based on results of the Cpk test, I made any necessary changes to the laser etch program and revalidated until a Cpk value of 1.62 was achieved.

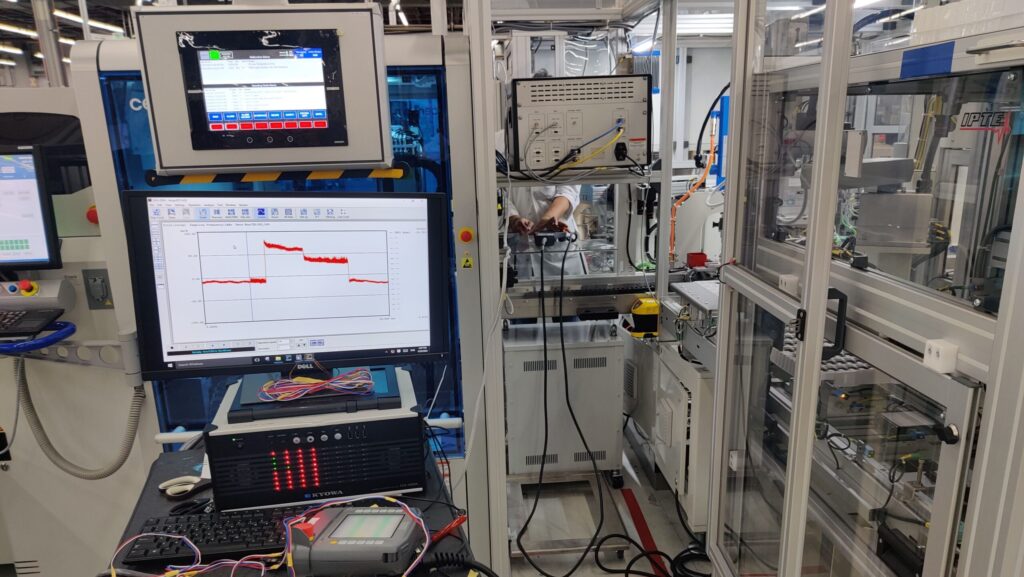

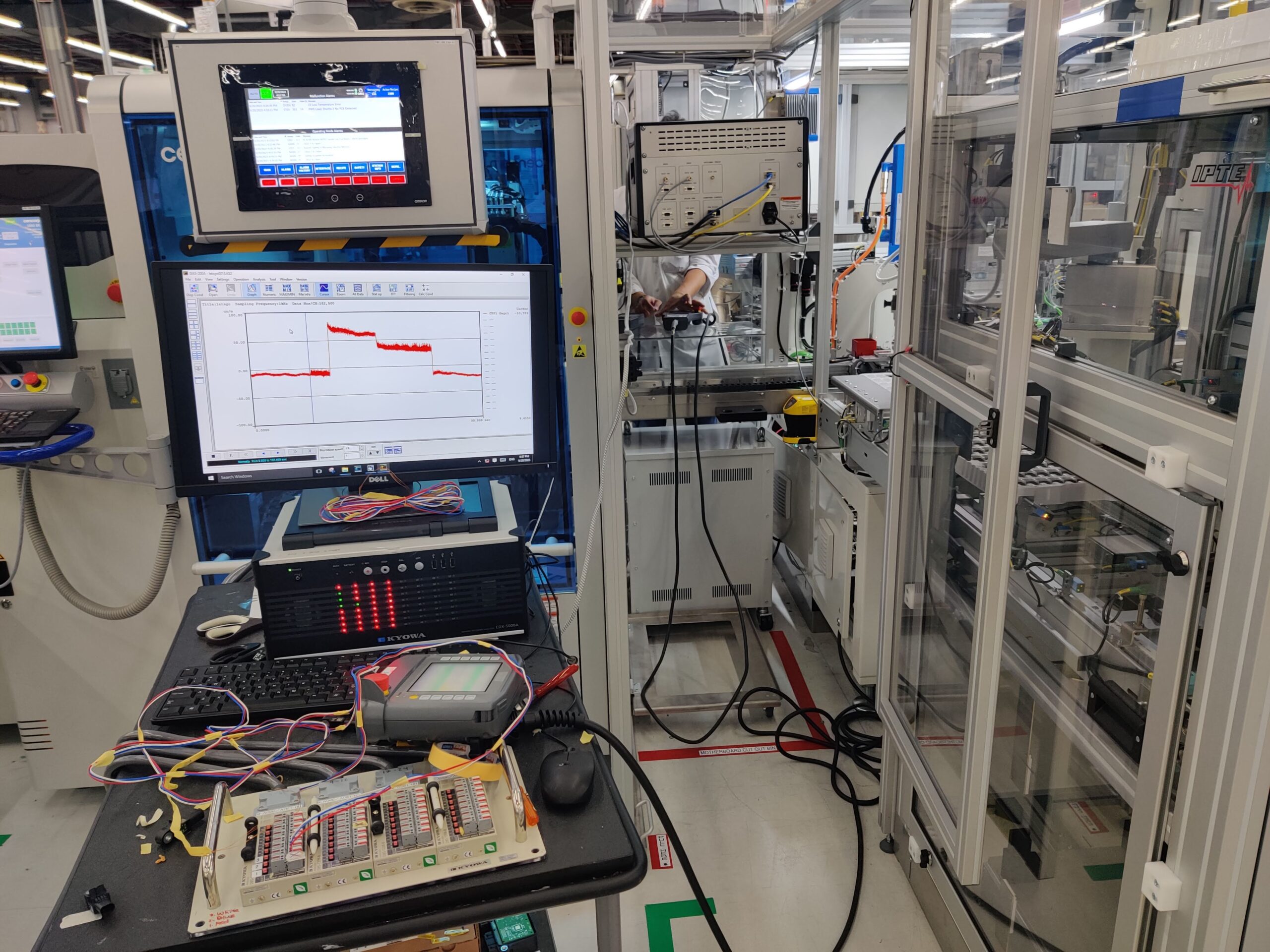

Strain Testing

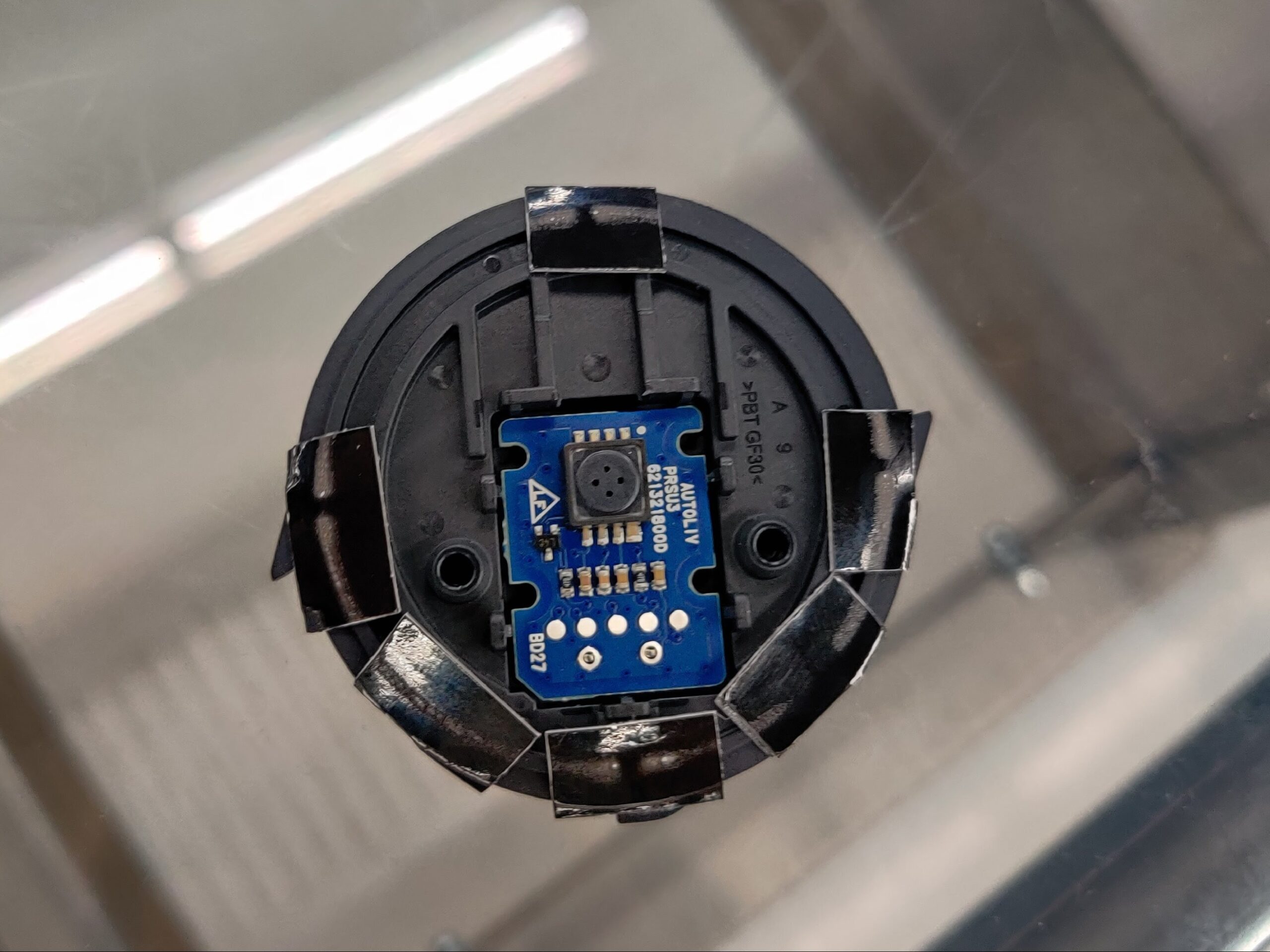

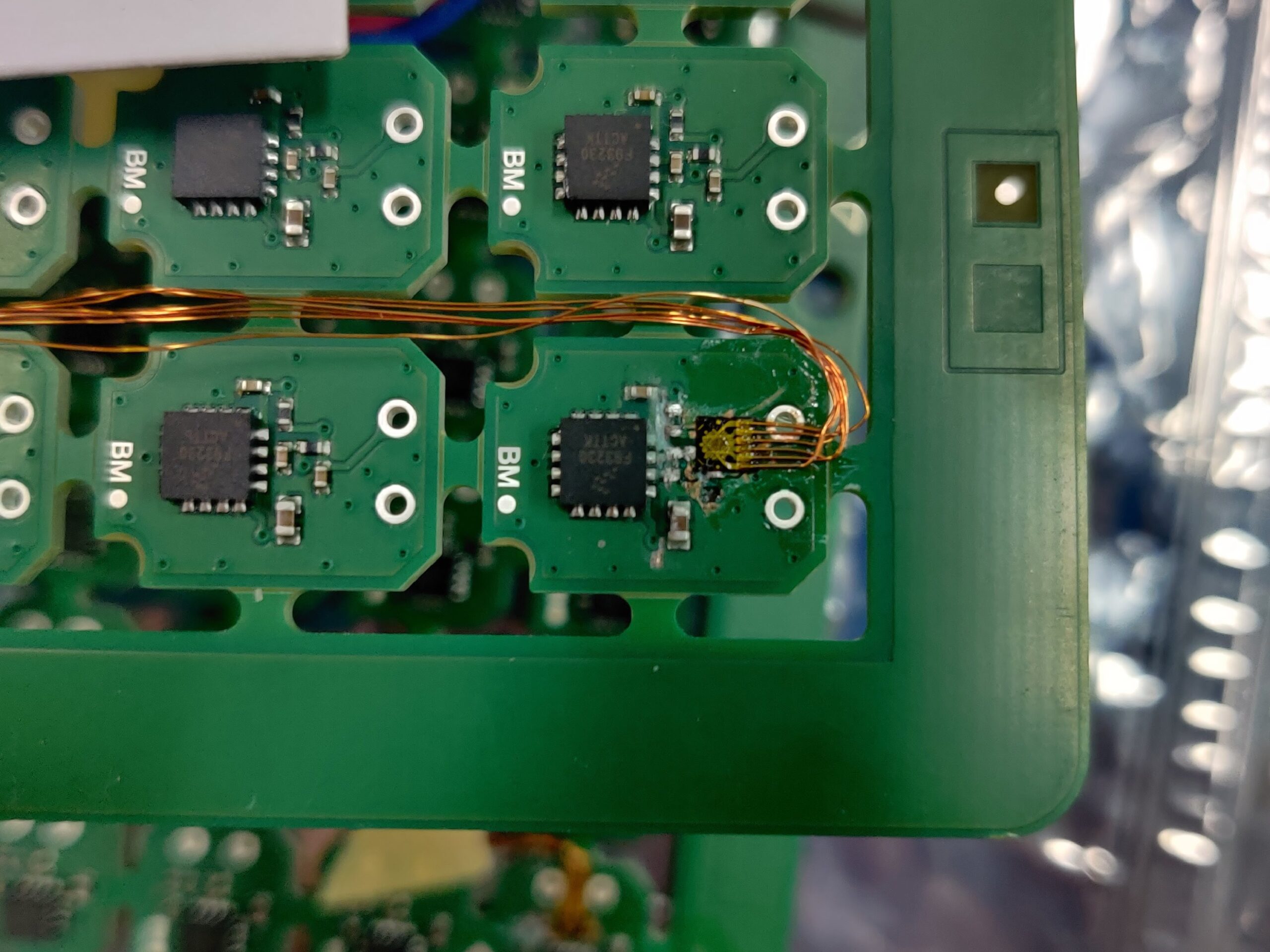

Conducted 21 strain tests on different products and processes when tooling would make contact with sensors on the PCBs to ensure strain was within safe limits. Applied strain gauges on samples and ran strain testing at least 3 times to generate a technical report. Interfaced with machines and processes by running the line in manual mode, scheduling line time as needed to run tests without disrupting existing production flow. Communicated with process and controls engineers to have them on-site to quickly assist with any troubleshooting. Had to get creative for some tests due to space and tooling limitations, ensuring strain gauge wires weren’t cut or accidentally pinched by anything while in-use.

3. Results

- Successfully launched 3 continuous flow production lines, capable of producing 742 modules per day.

- Reduced laser weld cycle time by 18%,

4. Challenges/Next steps

insert text here