Reverse Shoulder Arthroplasty Measurement System

Capstone Project

1. Project Overview

Problem statement

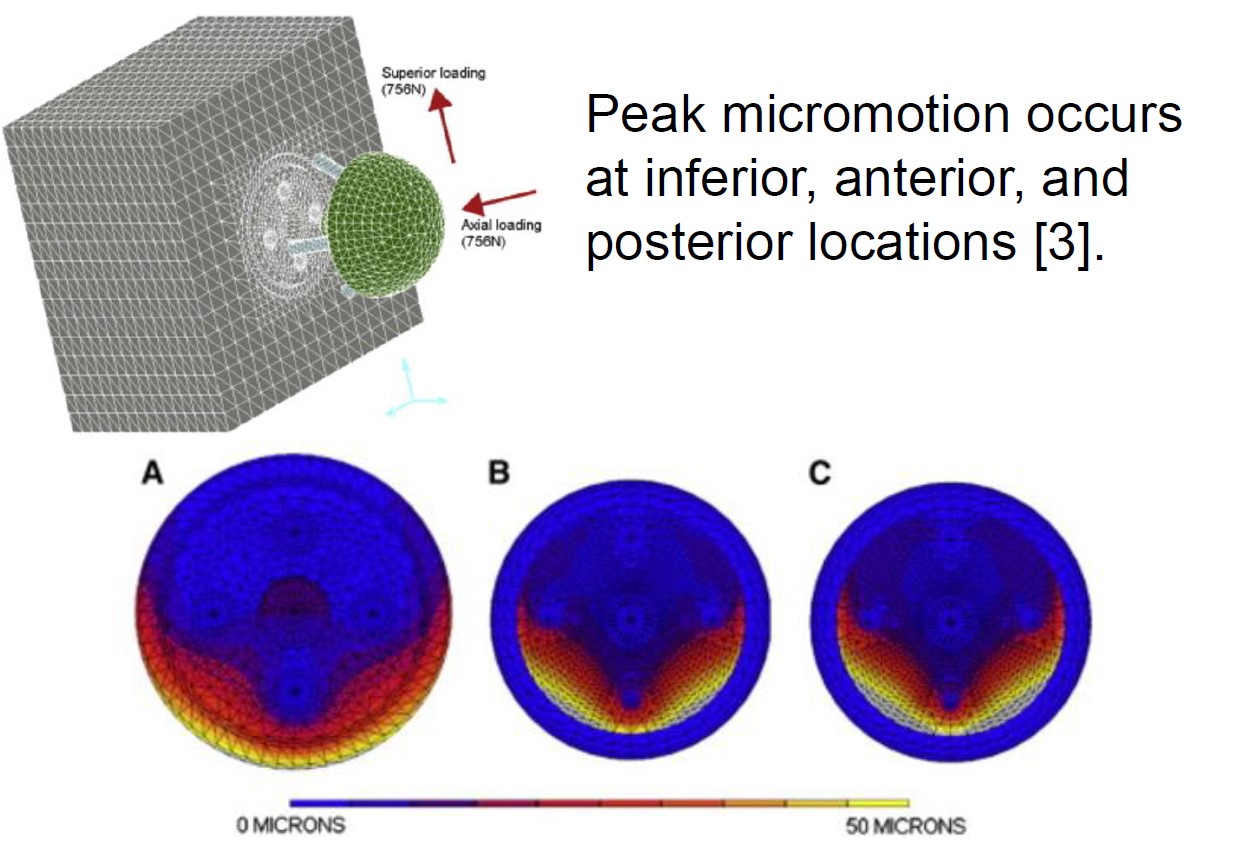

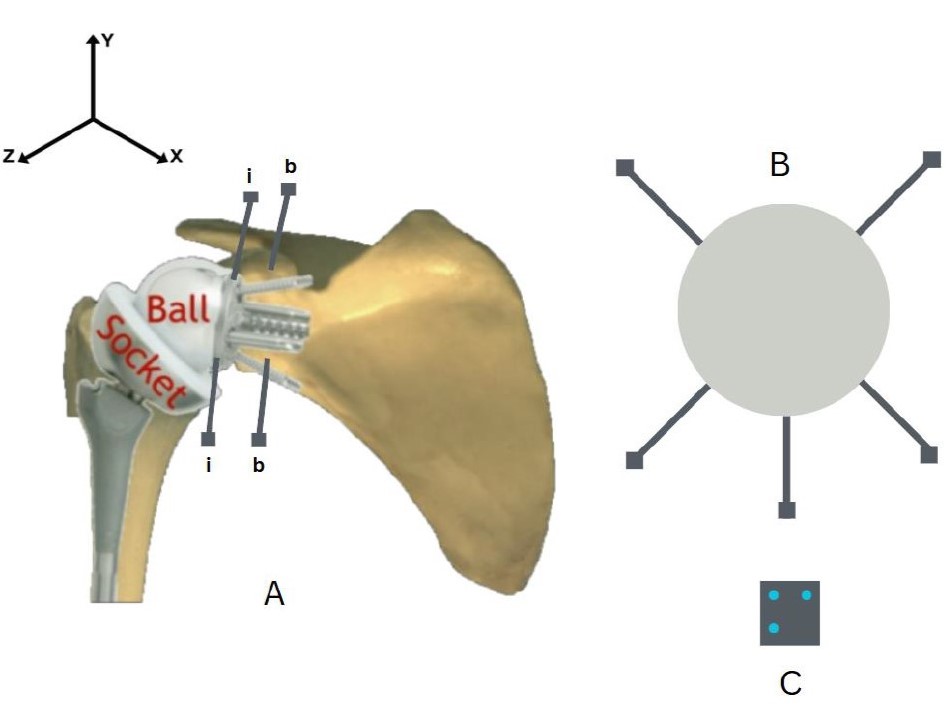

The leading cause of failure in total shoulder replacement surgeries via implant is known as the ‘rocking horse mechanism’, where loosening occurs between the bone and the implant when the relative micromotion exceeds 150 um.

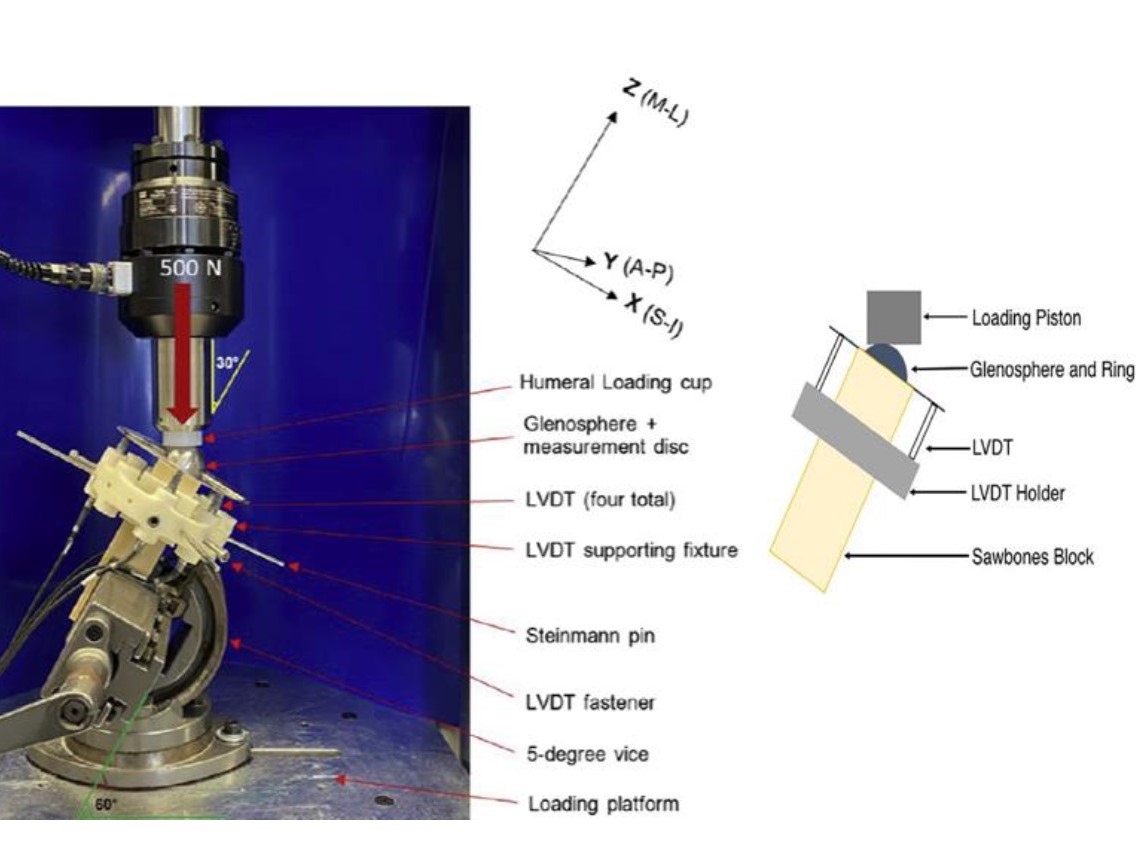

The current measurement system used to quantify this micromotion is limited to 3 d.o.f which is not a true representation of the shoulder joint.

Key Tasks

- Biomechanics

- Research & Development

- QFD

- FMEA

- Tolerance Stack-Up Analysis

Team

5 Mechanical Engineers

2. Process and Work

Problem Definition

The subject matter of this project was uncharted territory for us. This was an undergraduate capstone project, however it could’ve easily been a Masters or PhD research project. Total reverse shoulder arthroplasty is a relatively new and under-researched procedure. Thus, I spent a significant amount of time meeting with the client to define the problem and set a feasible and challenging scope. This consisted of requesting the scientific papers written by the client, researching global contributions in this field, and brushing up on my biomechanical knowledge of the shoulder joint.

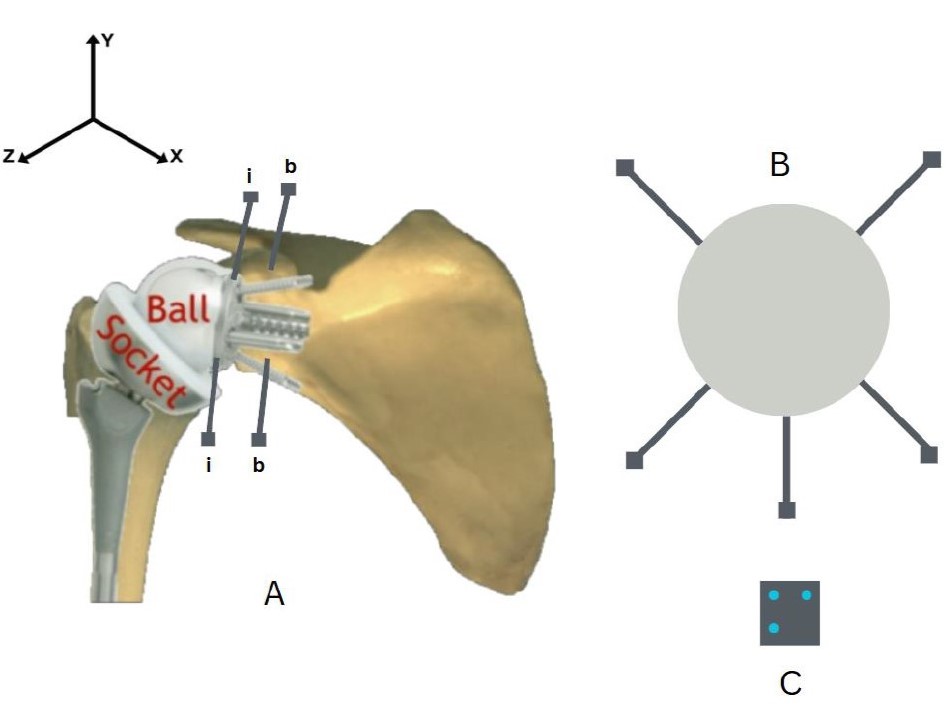

Design Proposal

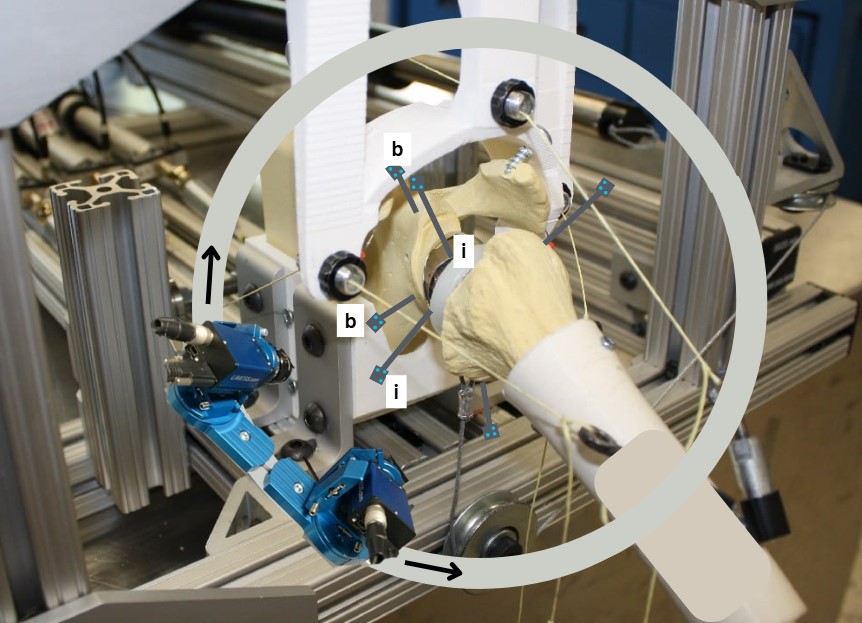

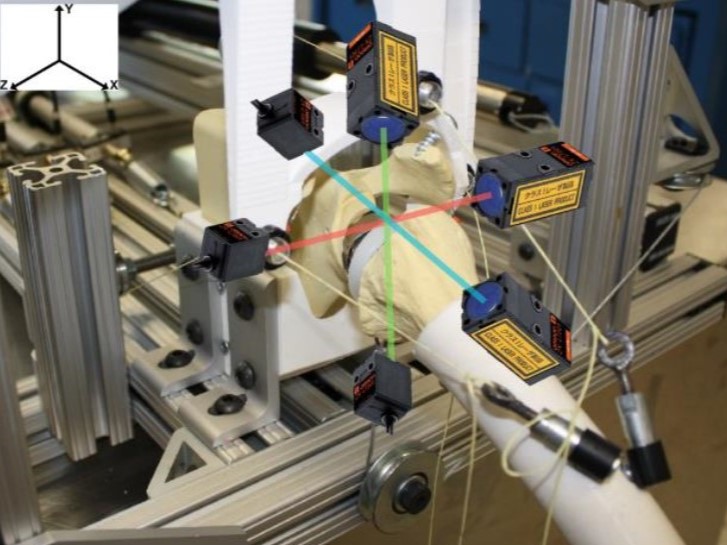

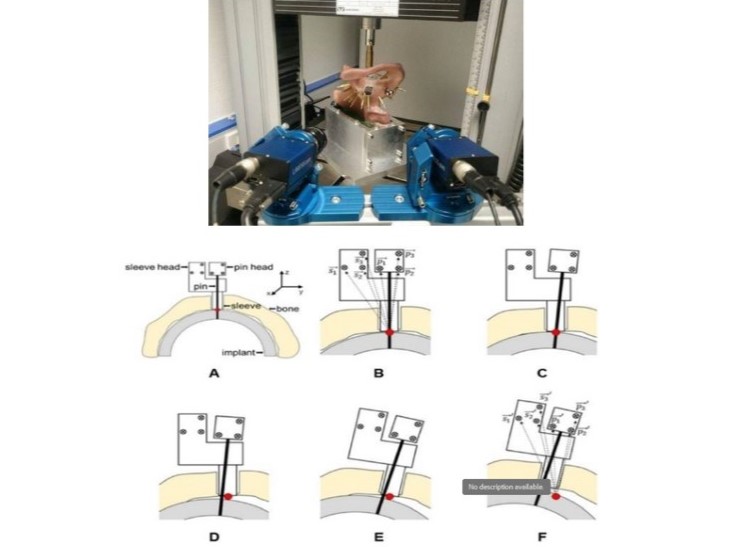

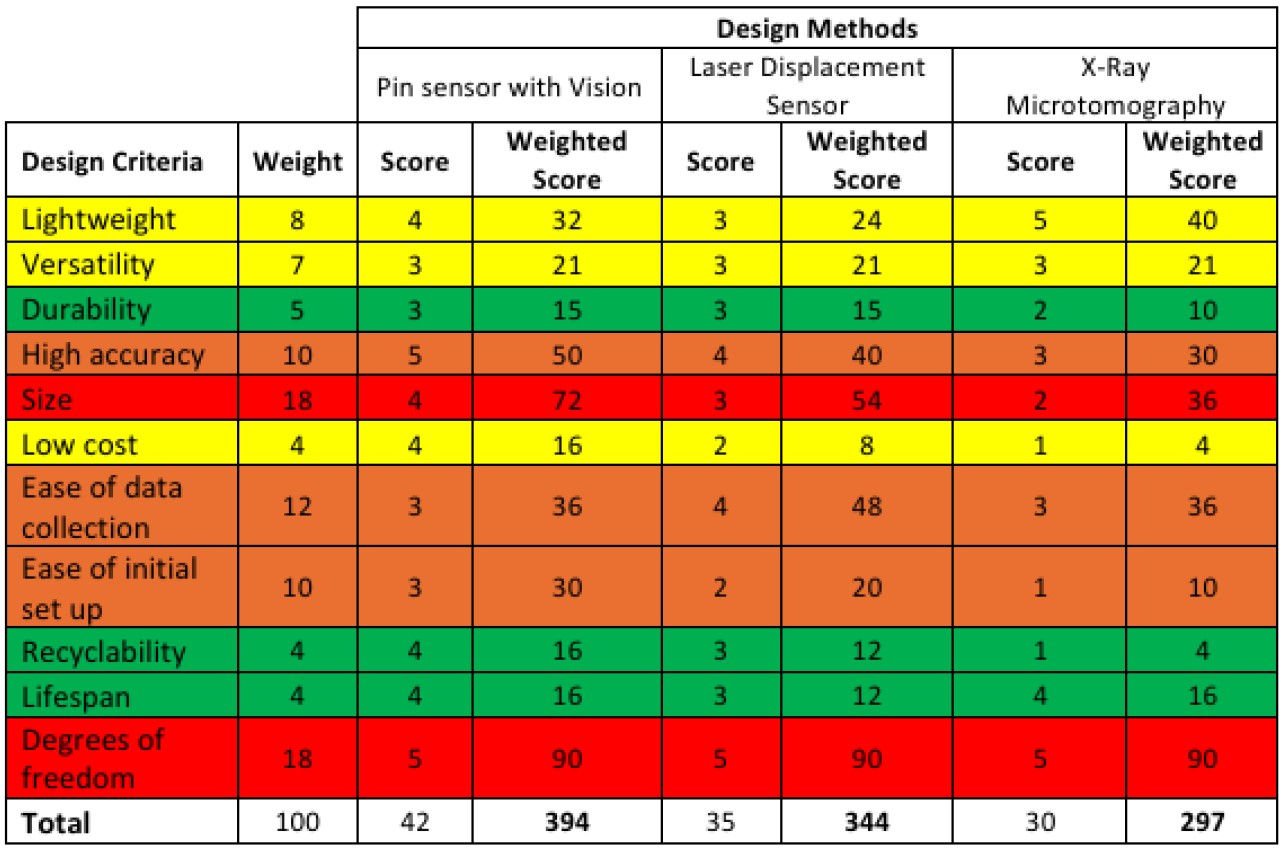

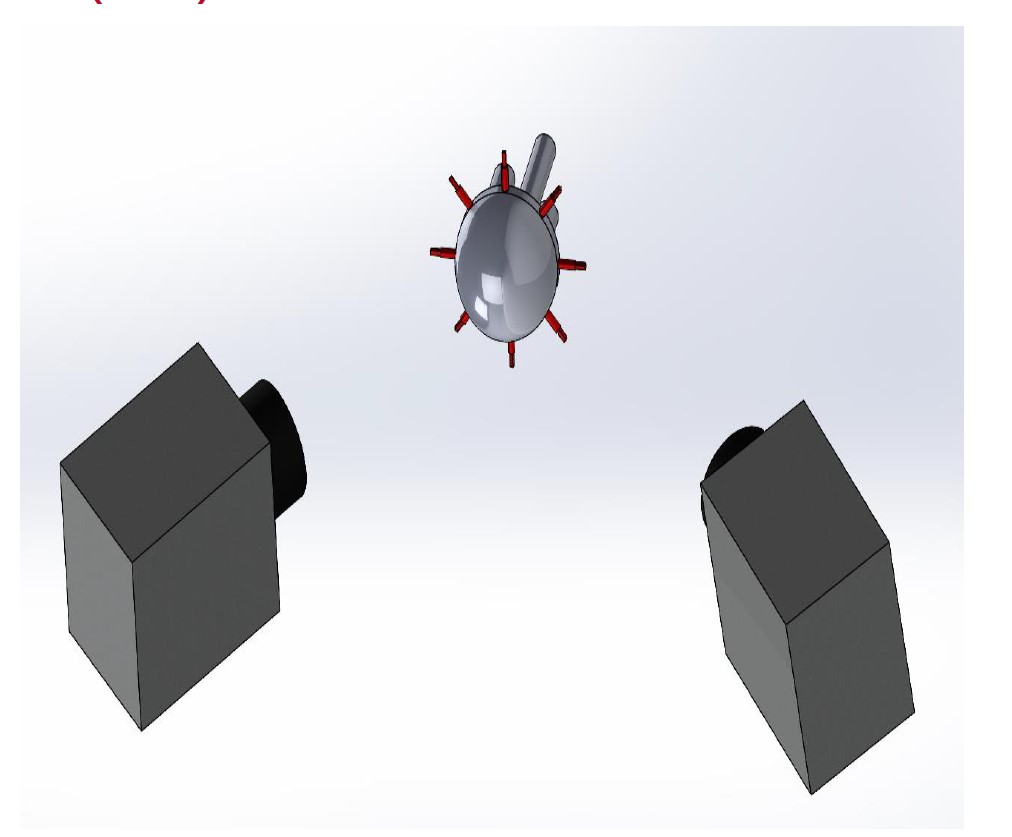

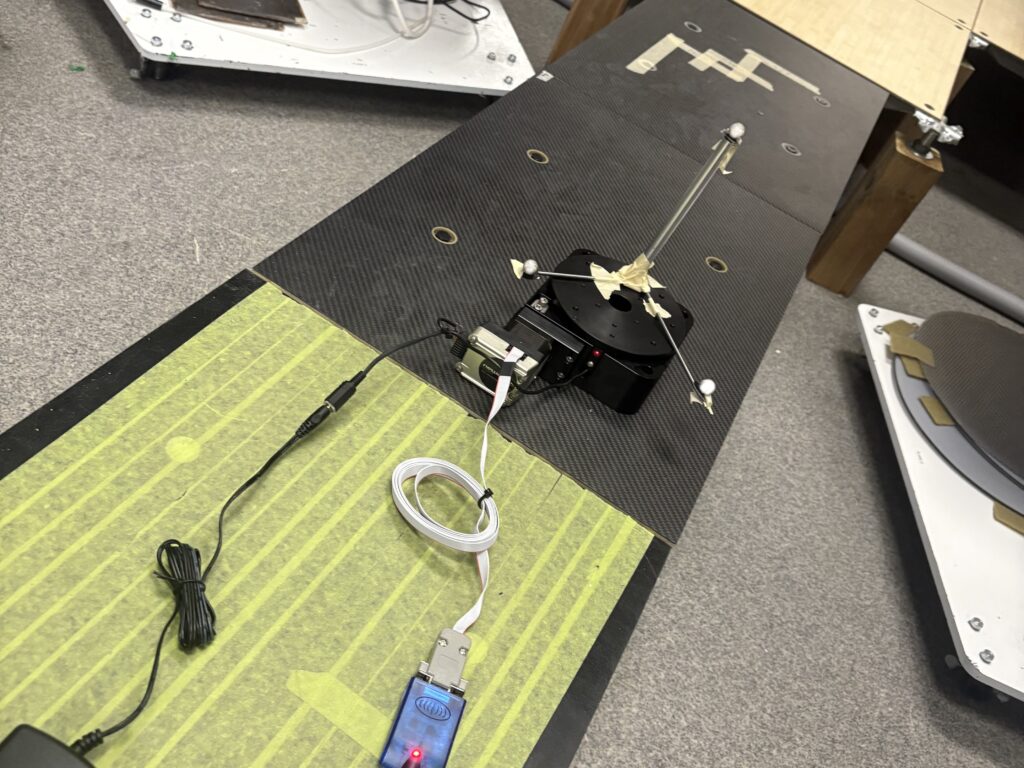

During my team’s research, we stumbled upon a group in Germany that developed a measurement system for this application using a combination of pins and optical cameras. We were inspired by this method and developed our own version with the resources we had available.

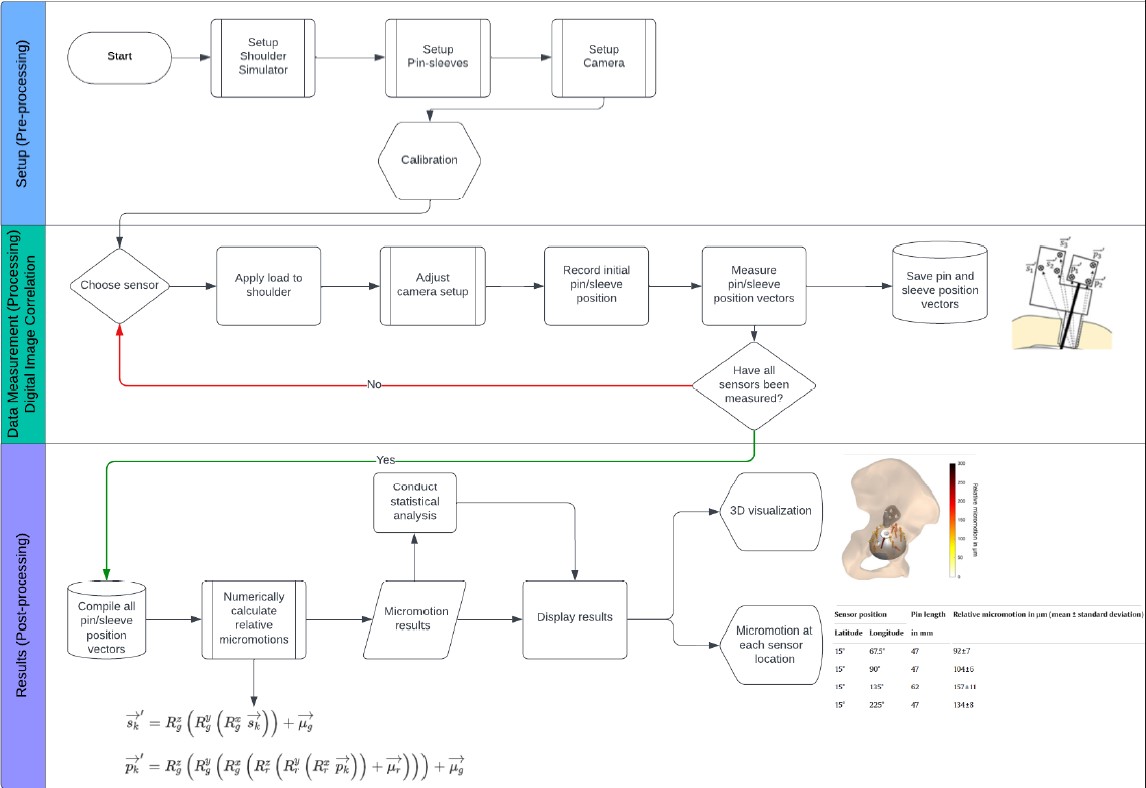

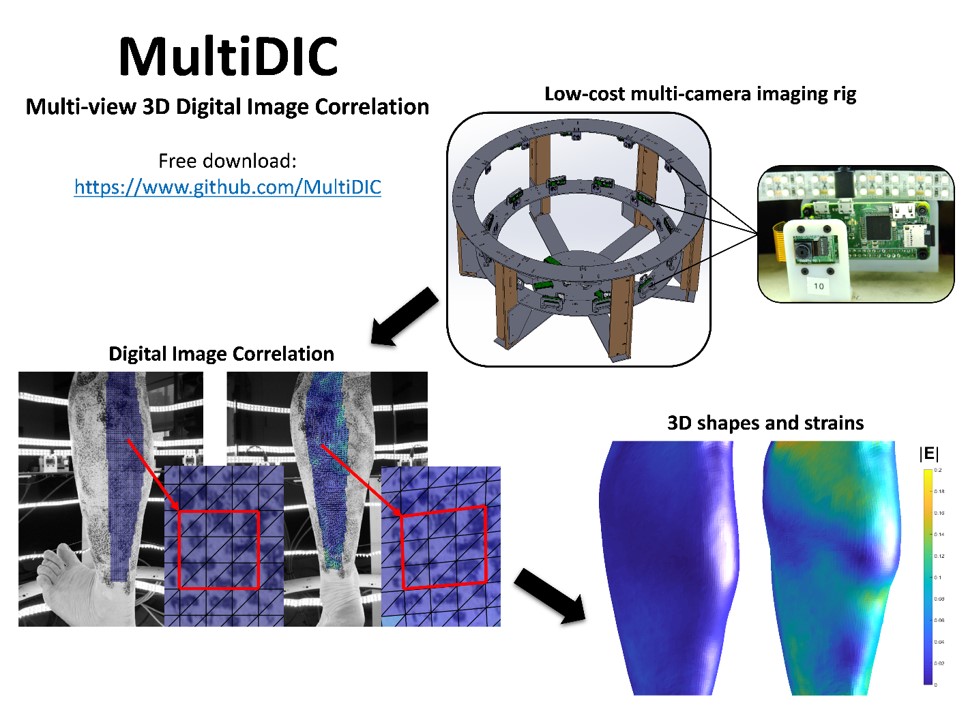

Digital Image Correlation

Upon further research, I discovered DIC technology that is often used in industry as a non-contact method of measuring strain fields using a minimum setup of 2 cameras.

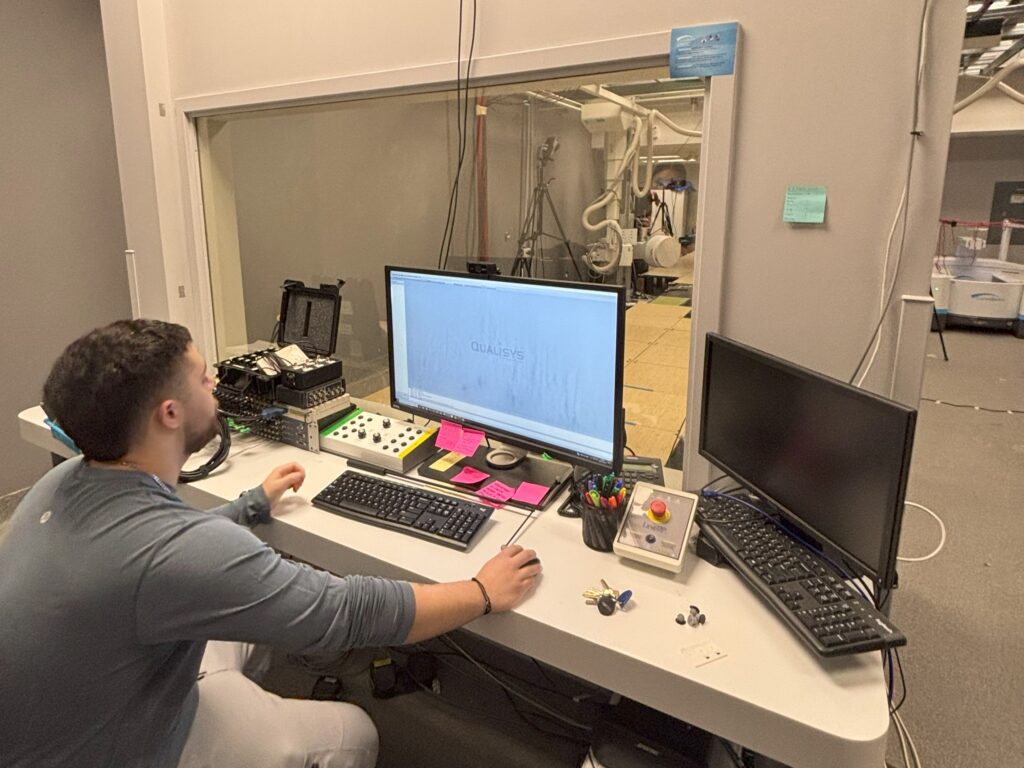

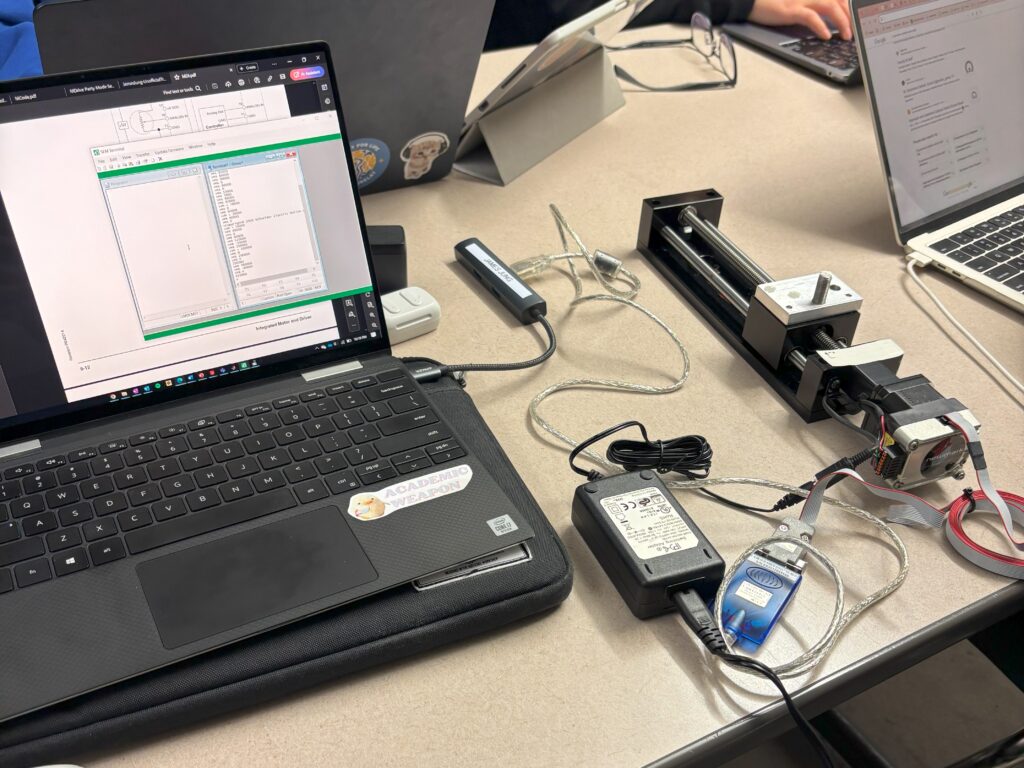

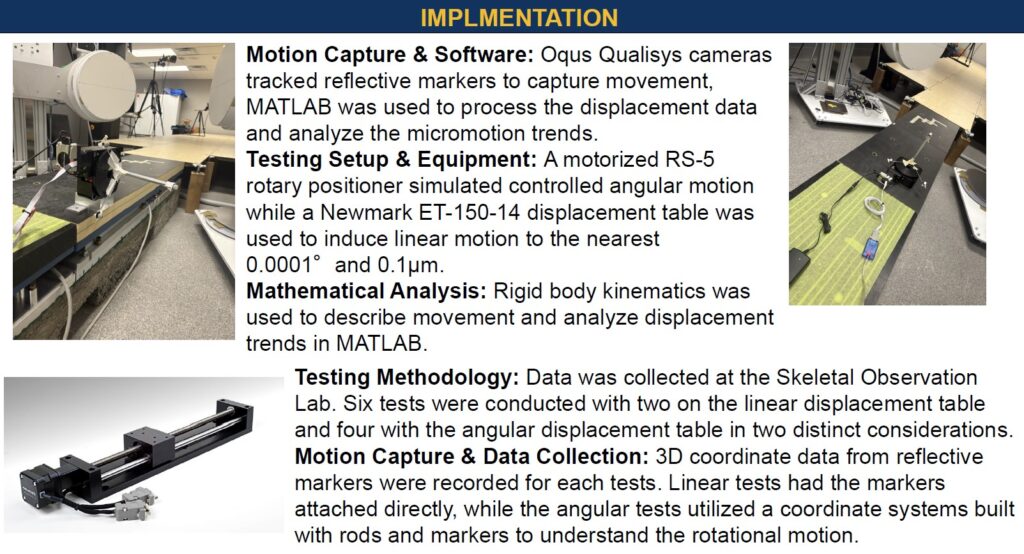

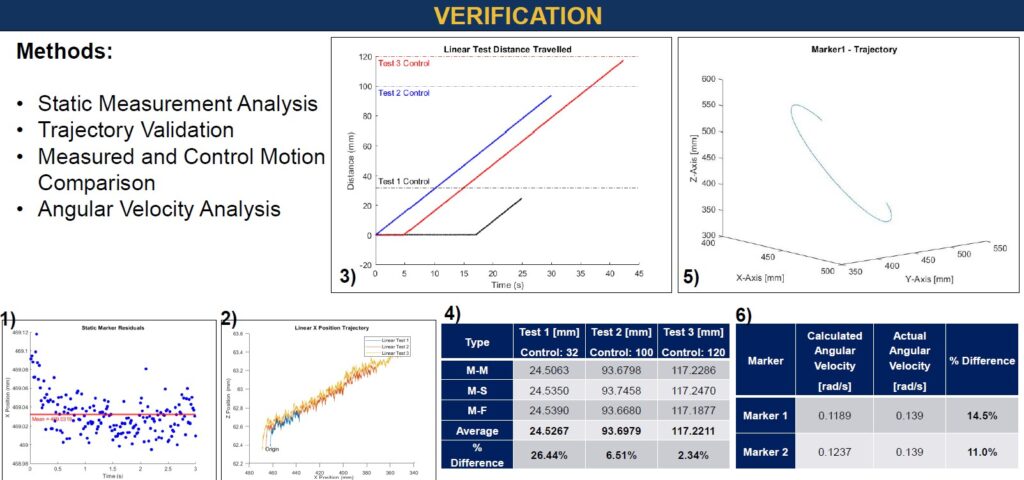

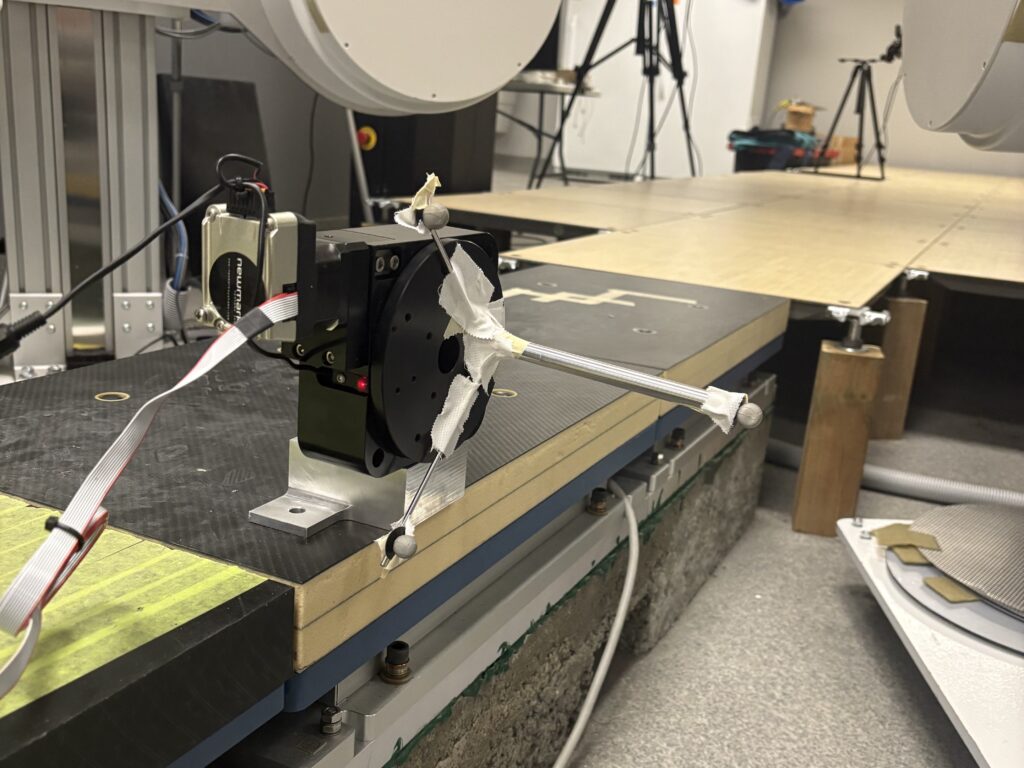

Design of Experiment

Using the Queen’s Skeletal Observation Laboratory’s state-of-the-art optical tracking systems, we designed an experiment to conduct a proof-of-concept study on leveraging DIC to measure micromotion in all 6 d.o.f. To save on costs, we reached out to other professors and took inventory of any relevant equipment that was available for our team’s use. We borrowed the equipment and designed a test we could conduct with what was available.