Veoneer

New Test Fixtures

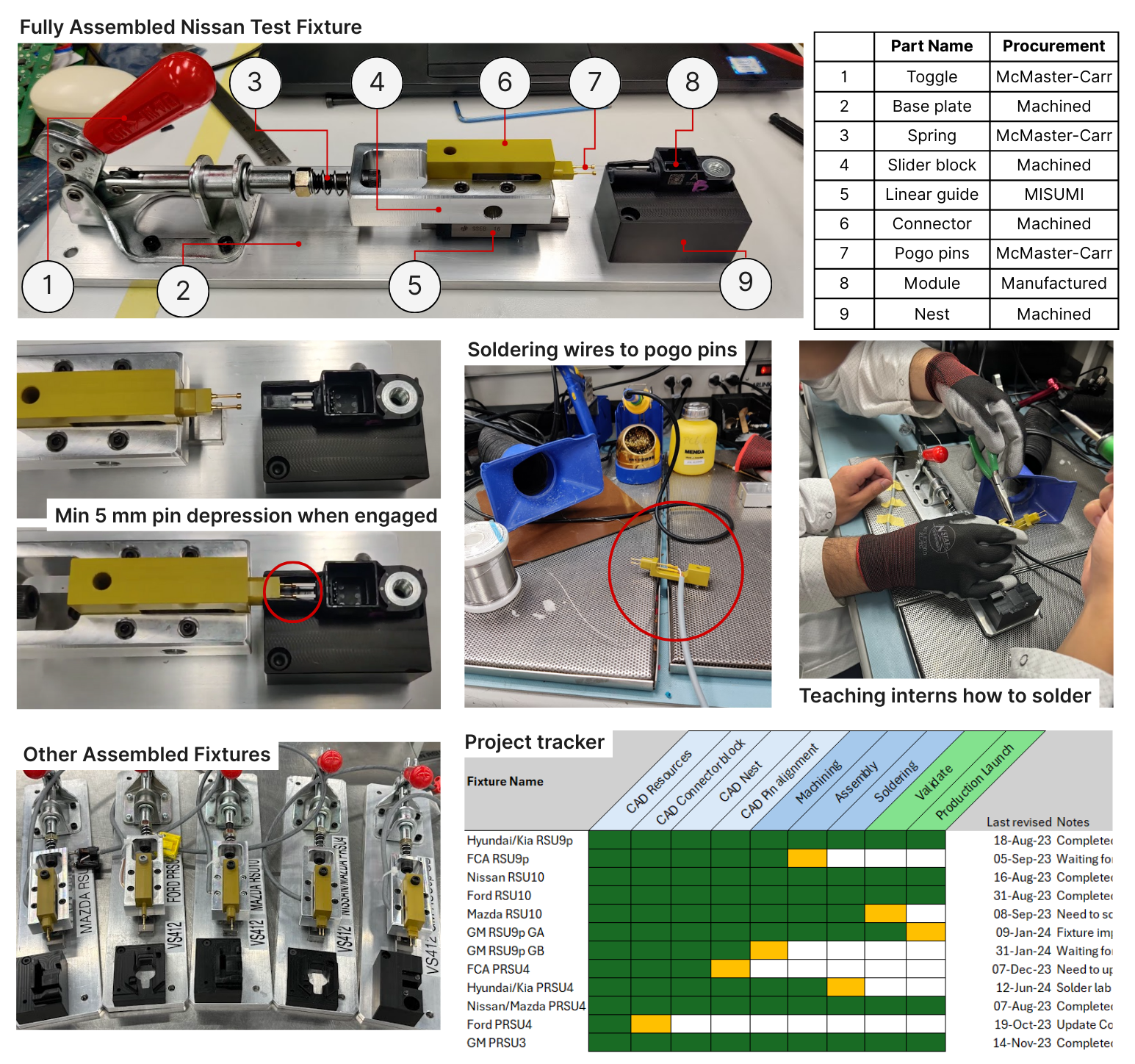

The New Product Introduction (NPI) team at Veoneer Canada Safety Systems needed 12 test fixtures to validate new products before delivering to customers. The project required electromechanical aptitude, parallel project management, and vendor communication.

During my 16 month internship at Veoneer, I took on a project to design, procure, and implement 12 new electromechanical fixtures to the production floor.

I designed all components and assemblies in SolidWorks, created manufacturing-ready drawings for fabrication, procured materials, soldered electrical components, and validated the fixtures in-use. Before beginning, I consulted with QCs to thoroughly define the problem and develop a solution satisfying their requirements (and factoring in their suggestions). I communicated with 5 vendors to acquire quotes and place purchase orders (POs), procuring from machine shops, McMaster Carr, MISUMI, and ULINE.

When engaged, the fixtures pushed a pair of electrical (pogo) pins against the connector pins of the product. A minimum 5 mm pin depression was required to establish an adequate connection to execute the test program. Dimensions to satisfy this requirement were determined using measurement tools in SolidWorks Assembly.

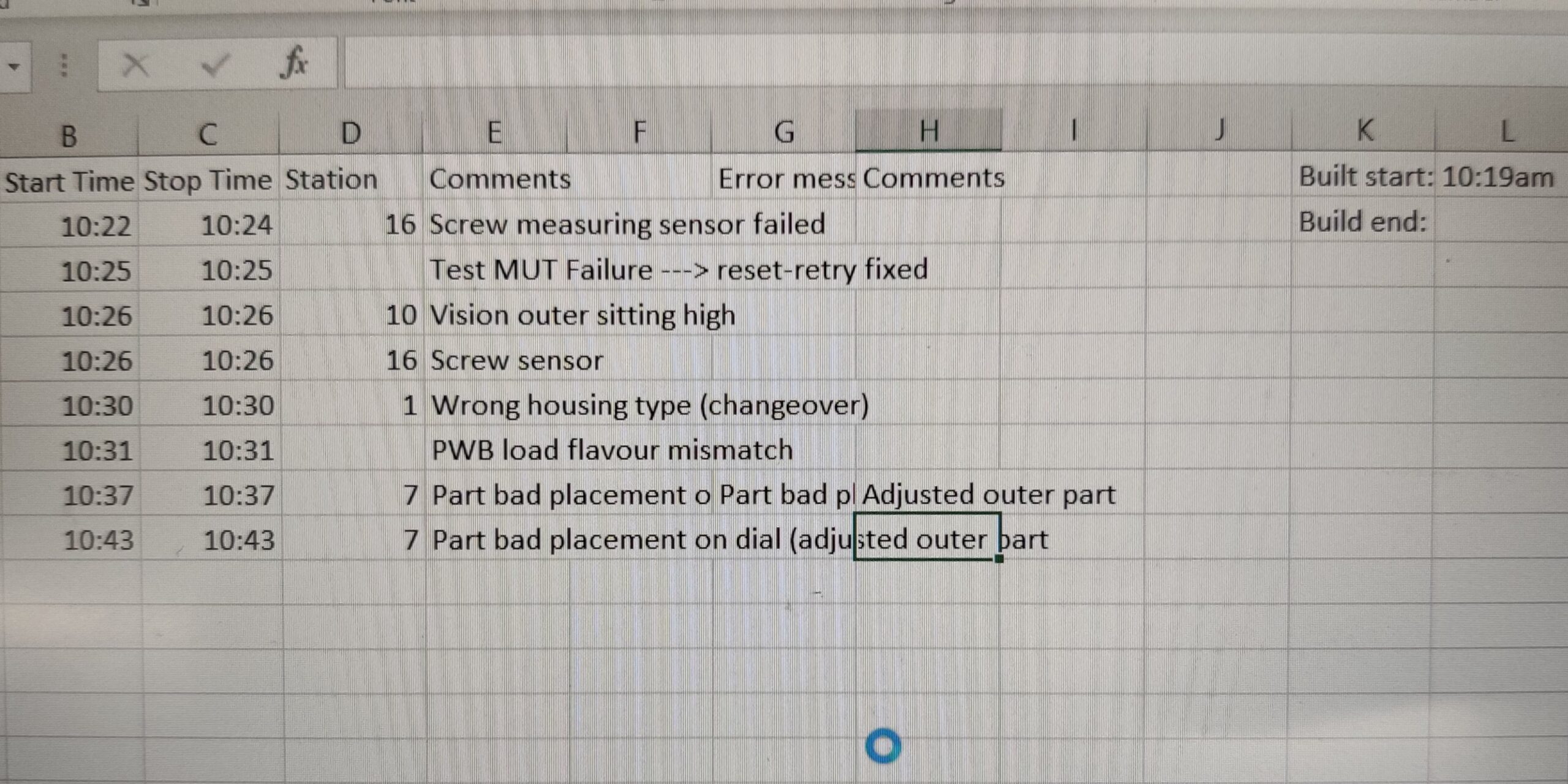

I created a project tracker to streamline efficiency and simultaneously work on different fixtures at different stages of completion. This project management system was initiated after experiencing downtime from waiting for files to be sent, POs to be approved, and material to ship.

Project Overview

New Electromechanical Product Development

Stakeholders

GM, Ford, Stellantis, Nissan, Mazda, Hyundai, Kia

Technical Environment

Lean Six Sigma, IATF 16949 Compliance (ISO 9001), Mechanical Design, GD&T

Scope of Work

SolidWorks, Soldering, Vendor Communication, Procurement, Stakeholder Engagement

Key Deliverables

Product Assembly, Installation, Technical Documentation

Process and Work

Process Capability (Cpk) and Gage R&R Studies

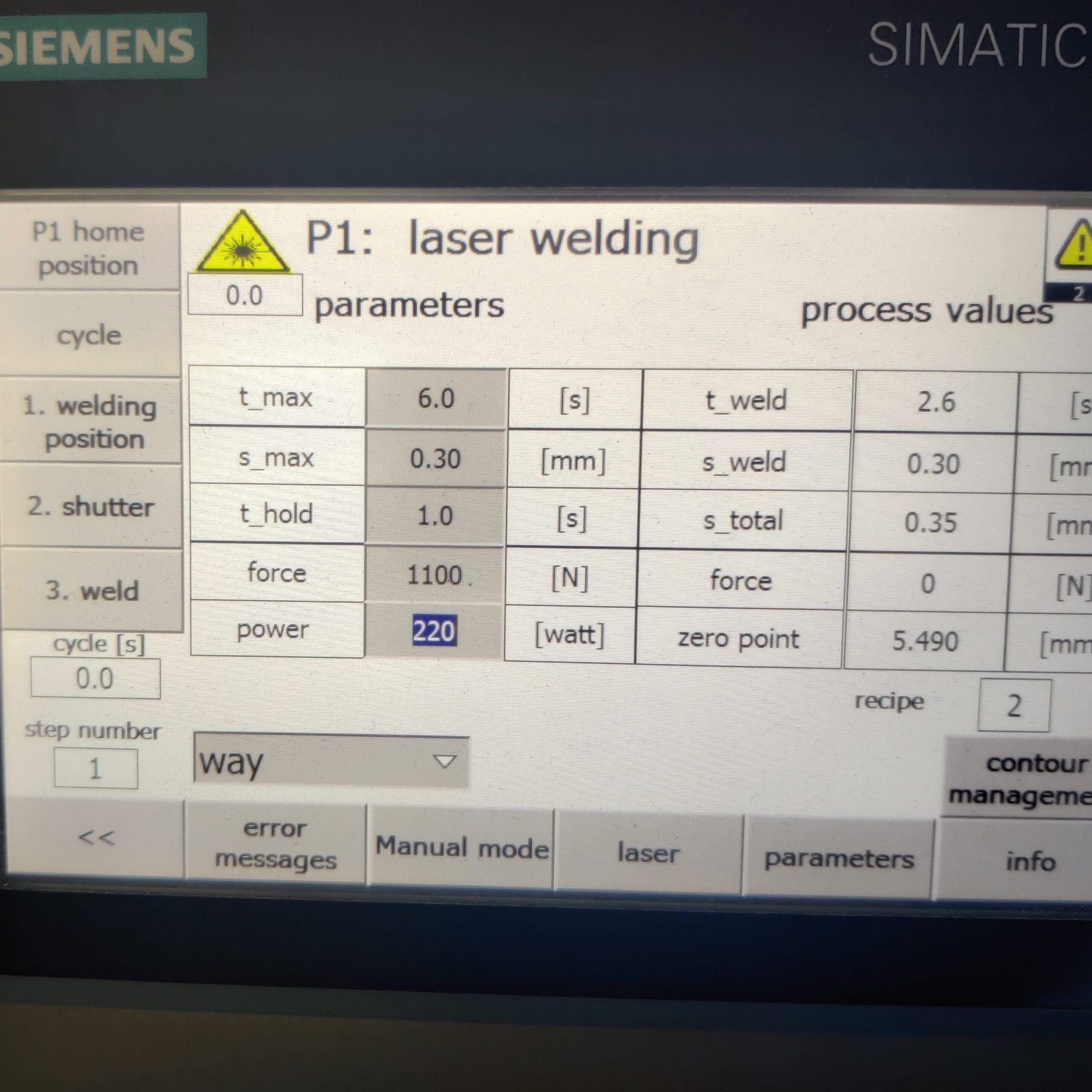

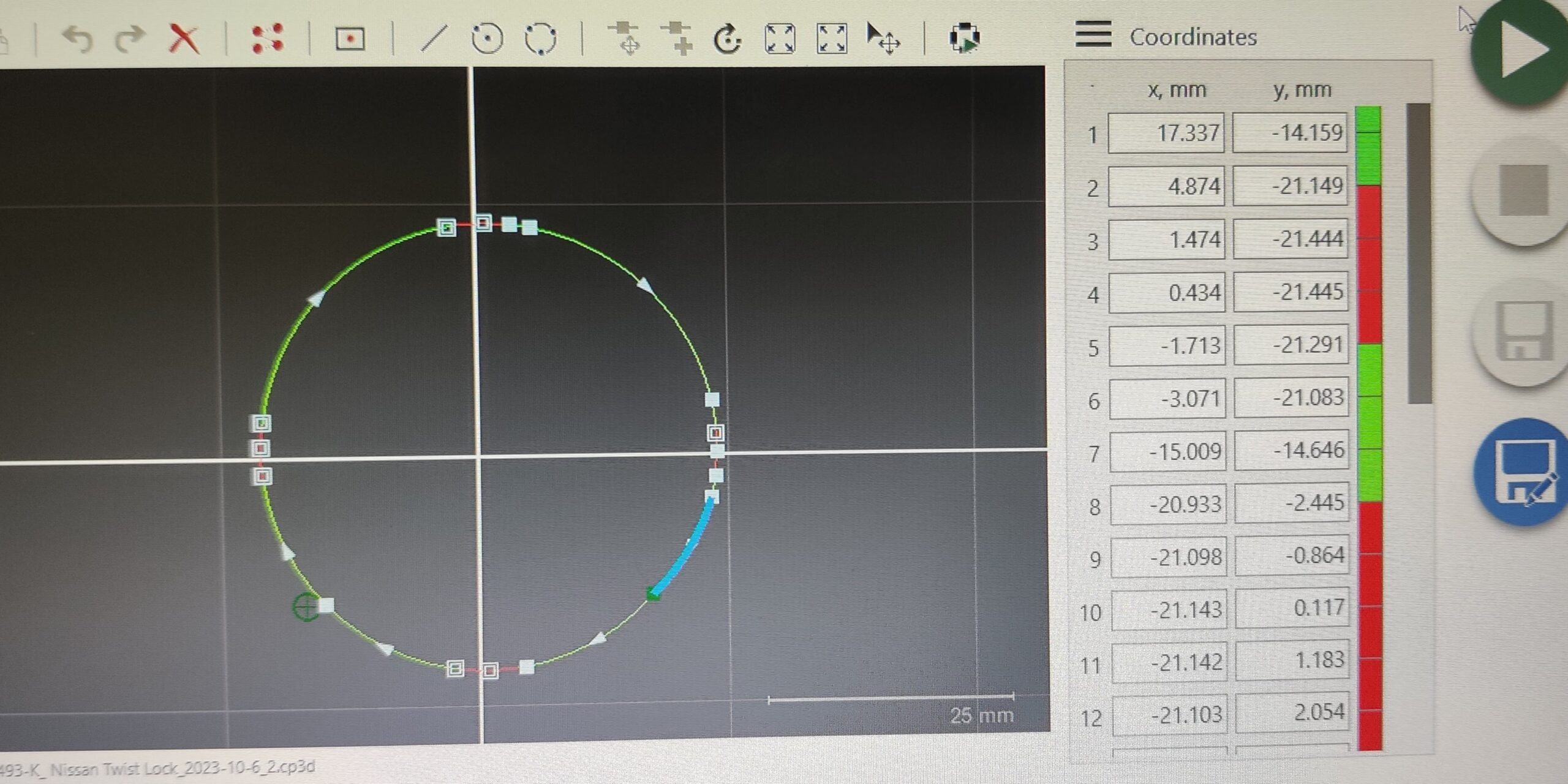

To ensure accuracy and repeatability over continuous cycles, Statistical Process Control (SPC) was used to validate each process:

- A minimum of 30, continuous samples were produced, measured, and recorded.

- Minitab was used to perform complex statistical calculations, verify compliance with standard acceptance criteria, and visualize the data to make evidence-based decisions.

- Results were presented for approval to advance project to the next phase.

Sensitivity Analysis

Often times, it required extensive troubleshooting and iteration to achieve the desired Cpk and GRR results. Root cause analysis and sensitivity analysis were used to streamline this process.

- The goal was to balance the trade-off between cycle time and quality.

- Variables were controlled and isolated to find the sweet spot.

- Developed intuition and technical understanding of how individual parameters affect the overall system.

Strain Testing

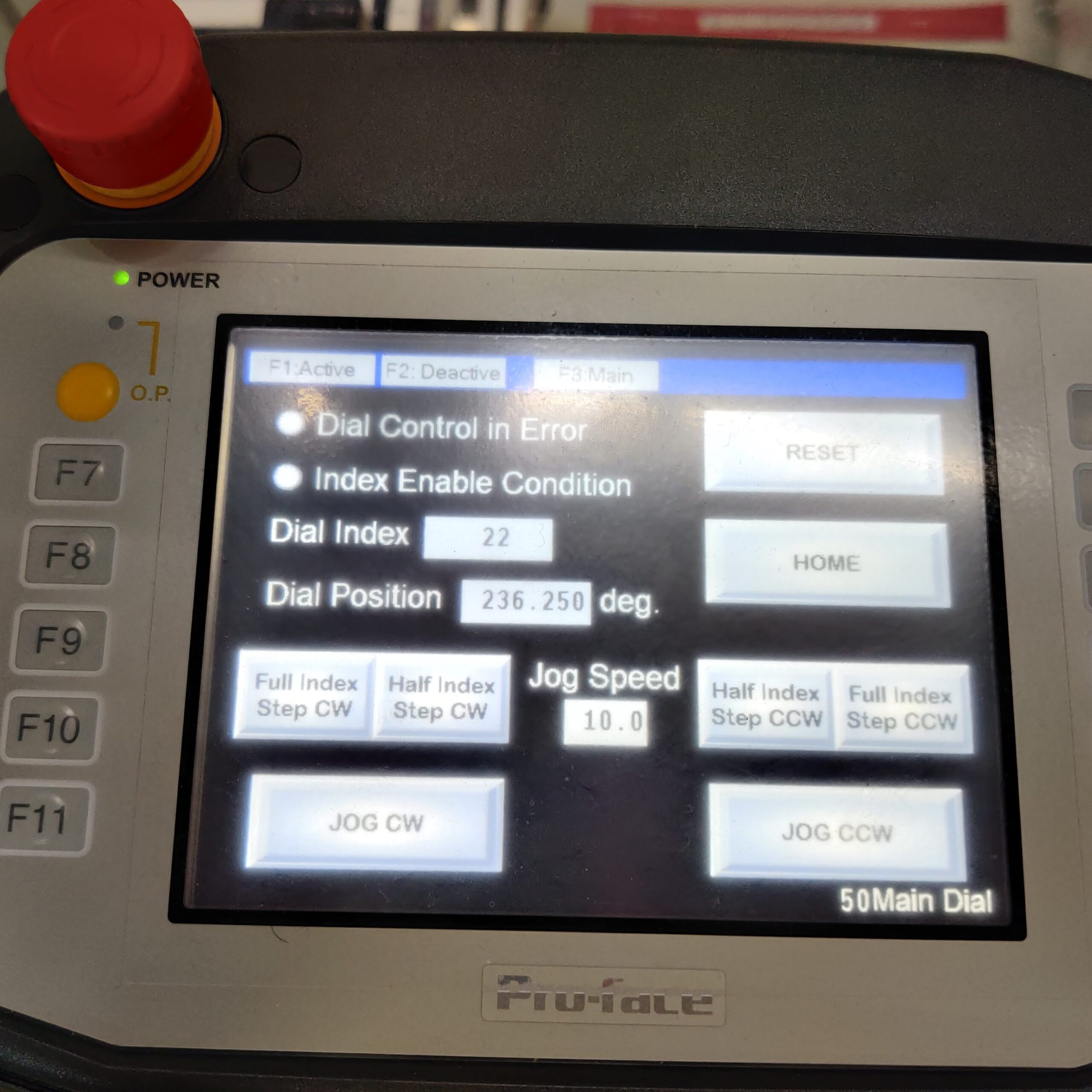

It’s important airbags deploy at the right time in the event of an accident. The sensor components are sensitive and frequently handled by robotic systems.

- I generated 10 strain test reports for 5 processes that involved physical contact with machinery or tooling.

- Strategically applied strain gages in critical locations while overcoming spatial constraints from moving equipment (pinched wires, tight spaces).

- Learned to interface with PLC and HMI for manual mode access.

Run-At-Rate Capacity Verification

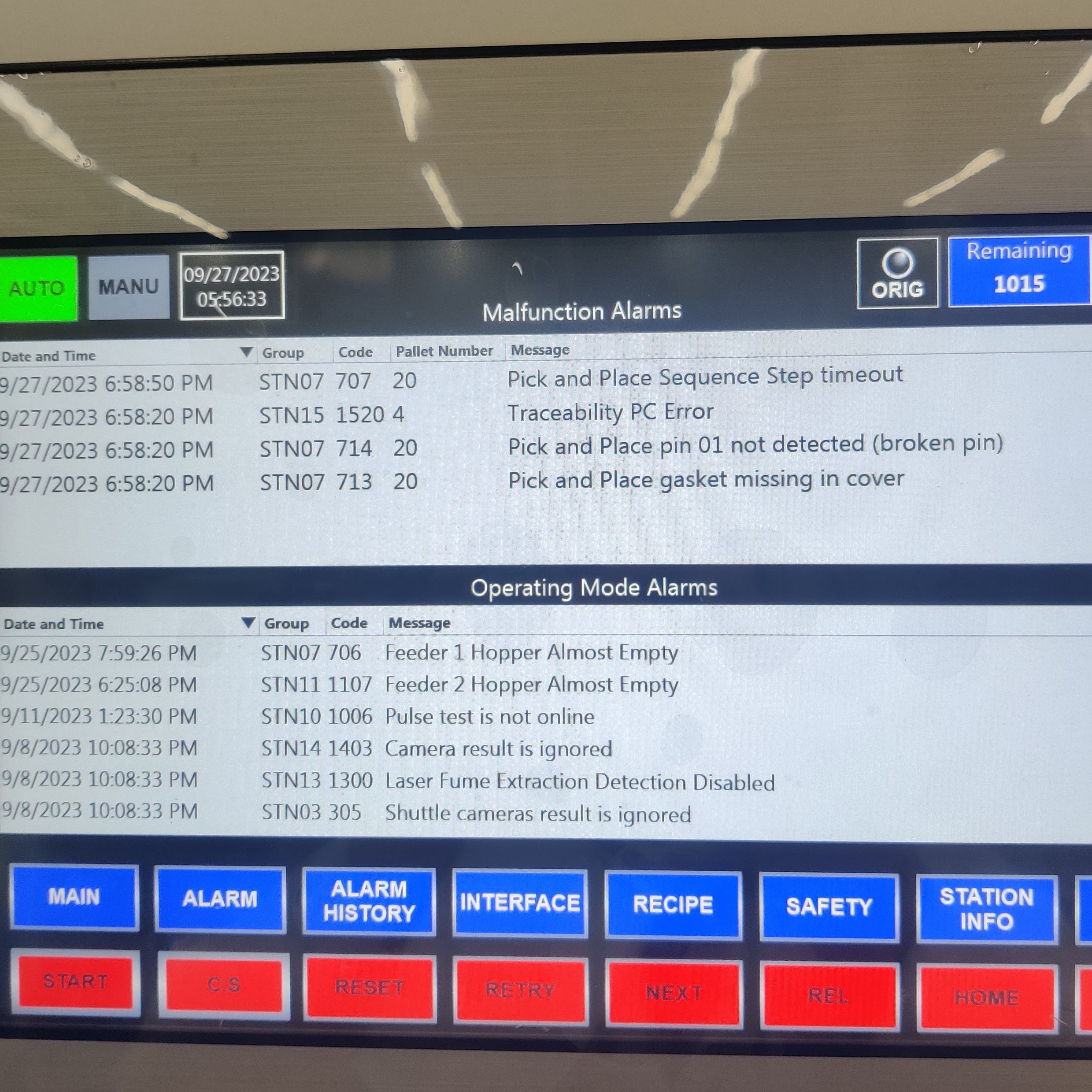

Once all individual processes were validated, run-at-rate builds were conducted to verify the line could meet the necessary production targets.

- Collaborated with product lead, project lead, test, and controls engineers to ensure the line ran without significant stoppages and met daily required production rate, per client’s forecasts.

- Performed PFMEA audits to ensure verify system’s ability to detect and mitigate process failures; i.e. failure-testing.

Learning Opportunities

Project Management

Keeping track of all 12 fixtures at different stages of development quickly became difficult to manage. So, I created a project tracking document to structure every phase of the project and provide details for each fixture (i.e. level of completion, current status, remaining phases, target deadline, etc.). This allowed me to develop multiple fixtures in parallel and ensure efficiency (i.e. assembling another fixture or troubleshooting it while the current fixture is waiting for parts to ship).

Communicating Design Intent

Four fixture components (2 of them being product-specific designs) were fabricated by producing CAD drawings and sending them to local machine shops. This was an opportunity to create drawings with practicality and feasibility in mind. I learned to design for manufacturing, taking into consideration the limitations of manufacturing processes using circular bits (i.e. interior right-angled corners). I also learned to tolerance and calculate clearance using GD&T.

Vendor Communication

The procurement process involved sending many emails to different suppliers and vendors. I learned to send professional emails, following up when needed, and requesting quotes and invoices.

Retrofit Design

The product-specific parts of every fixture (nest and connector) were designed by retrofitting existing tooling and machinery that interacted with the products in a similar manner on the production line. The CAD of these parts were extracted from the CAD assemblies of the line and used to obtain the critical dimensions and geometry.

Process Capability (Cpk) and Gage R&R Studies

To ensure accuracy and repeatability over continuous cycles, Statistical Process Control (SPC) was used to validate each process:

- A minimum of 30, continuous samples were produced, measured, and recorded.

- Minitab was used to perform complex statistical calculations, verify compliance with standard acceptance criteria, and visualize the data to make evidence-based decisions.

- Results were presented for approval to advance project to the next phase.

Process Capability (Cpk) and Gage R&R Studies

To ensure accuracy and repeatability over continuous cycles, Statistical Process Control (SPC) was used to validate each process:

- A minimum of 30, continuous samples were produced, measured, and recorded.

- Minitab was used to perform complex statistical calculations, verify compliance with standard acceptance criteria, and visualize the data to make evidence-based decisions.

- Results were presented for approval to advance project to the next phase.